Advantage

The machine adopts an explosion-proof industrial socket, which makes the operation safer;

The machine adopts a thickened aluminum clamp, which is more stable and durable;

The heating plate adopts an independent temperature control system, which makes the temperature control more stable.

It is sprayed with Teflon coating, which will not stick to the pipe;

The milling cutter adopts a three-stage torque high-power motor, which makes milling more stable;

The machine adopts an integrated timer to record the time period of heat absorption and cooling, which is more convenient to use;

The machine adopts a high-precision shockproof pressure gauge, which is resistant to low temperatures and has a more accurate pressure reading.

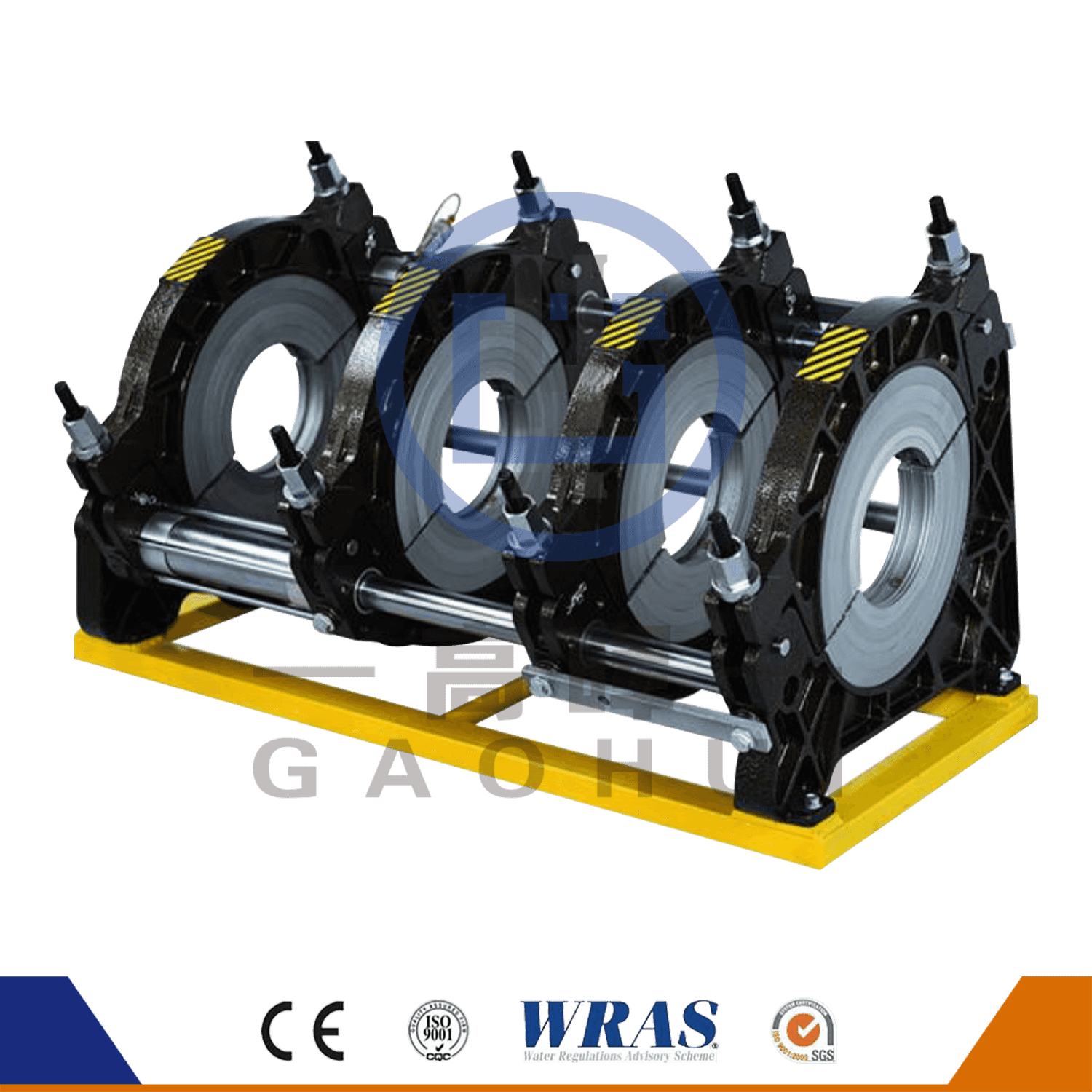

The 315 Hydraulic semi-automatic hot-roasting welder (Boutique/High-quality model) is a high-performance pipe welding machine designed for hot-melt joining of PE, PP, PVDF, and other plastic pipes. This model features an explosion-proof industrial socket to ensure operational safety; thickened aluminum clamps enhance the equipment's stability and durability, making it suitable for high-intensity use. The heating plate is equipped with an independent temperature control system to ensure precise and stable temperature control, while a Teflon coating prevents pipe adhesion and improves work efficiency. A three-speed torque high-power milling cutter motor makes the cutting process smoother and improves welding accuracy. Furthermore, an integrated timer records heating and cooling times, allowing operators to control the timing of each stage and ensure welding quality. A high-precision, shockproof pressure gauge provides accurate pressure data and has excellent low-temperature resistance, ensuring stable operation in various environments. It is suitable for pipeline installation and maintenance in industries such as oil, natural gas, water conservancy, and power, and is ideal for applications requiring high welding accuracy and safety.

English

English русский

русский عربى

عربى