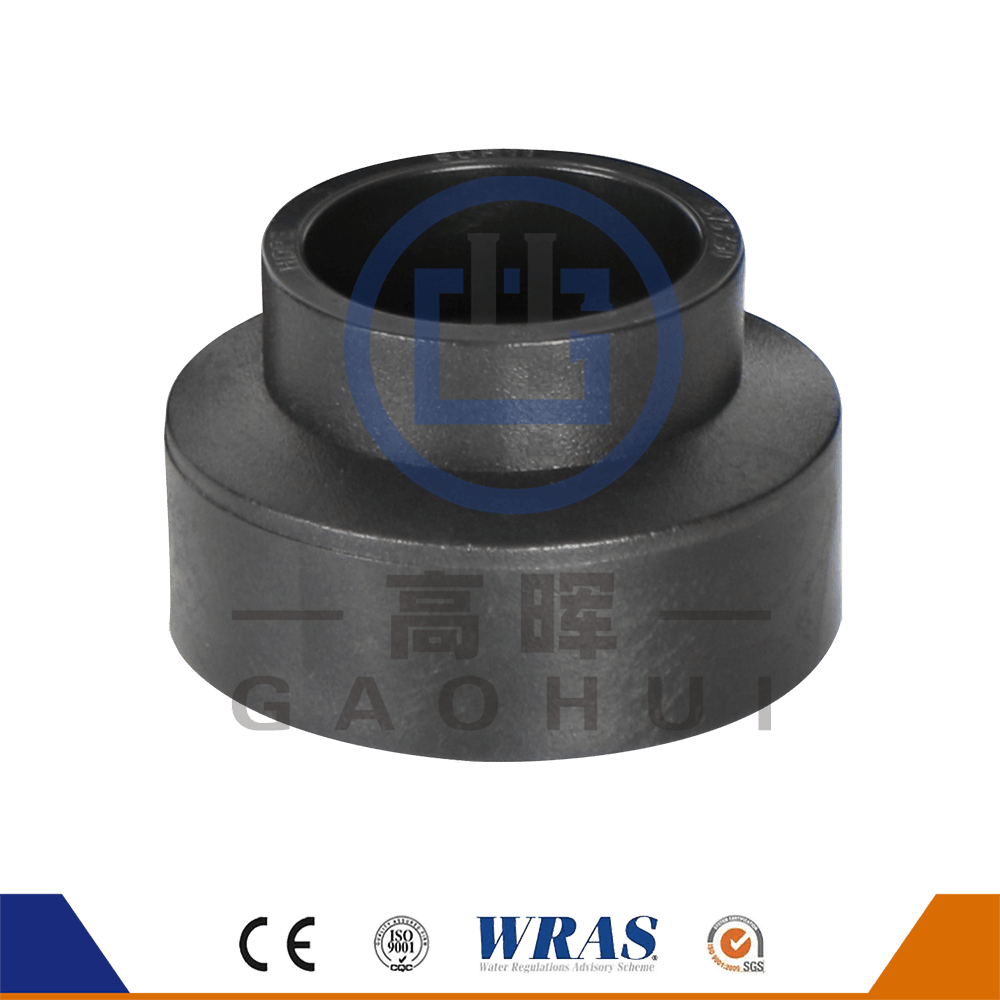

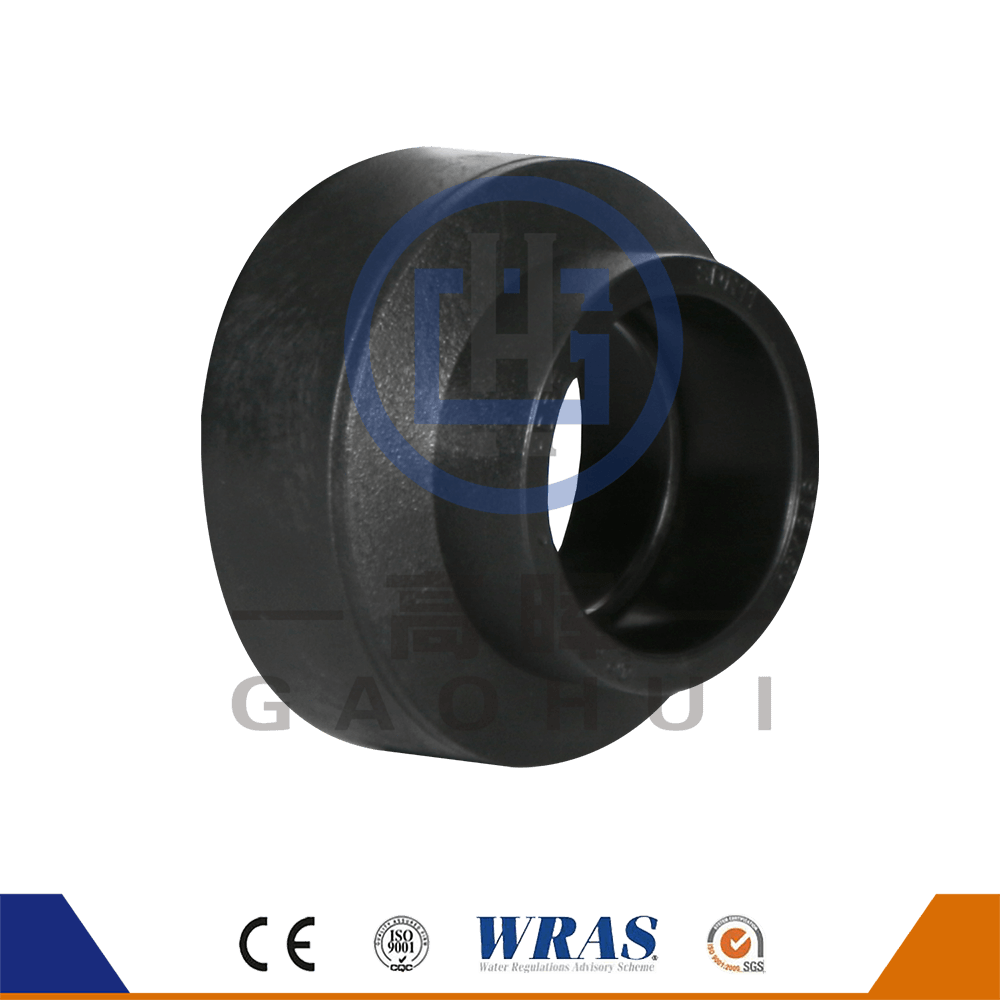

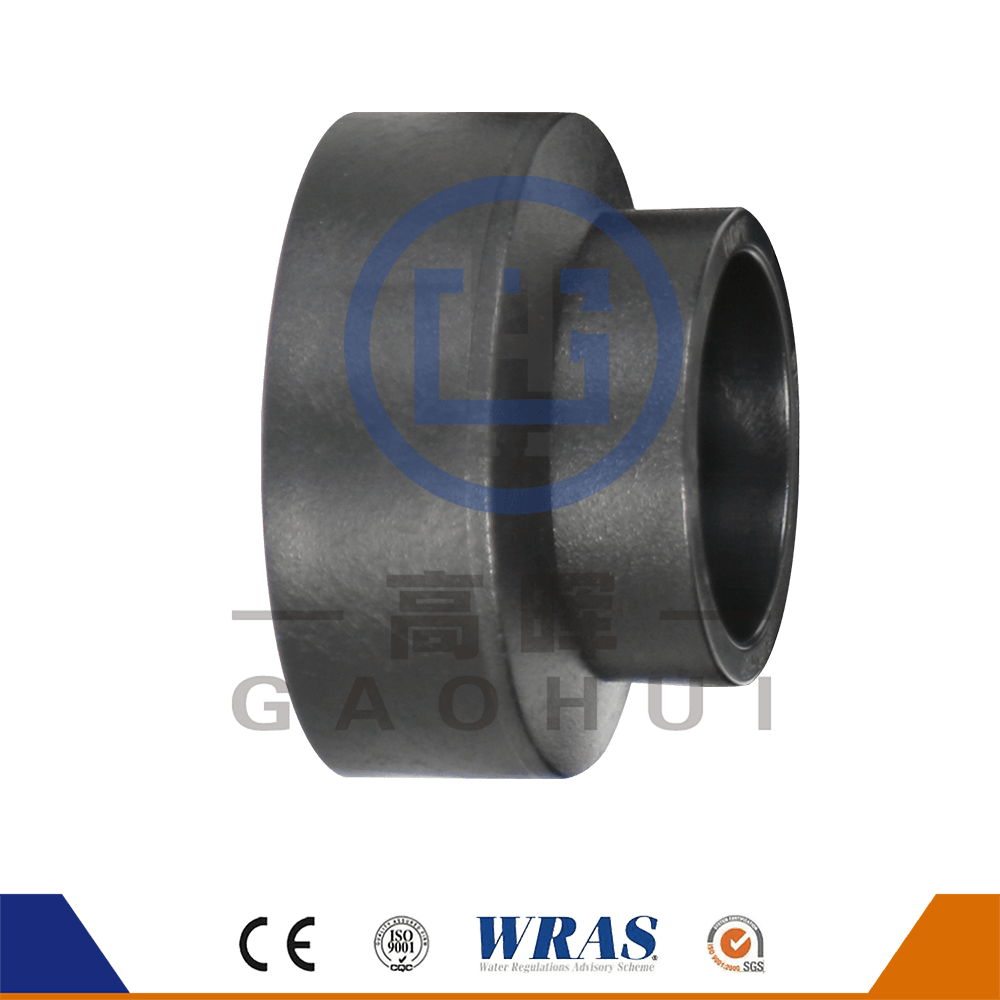

HDPE socket fusion reducers are fittings used to connect two pipes of different diameters in a HDPE (high-density polyethylene) piping system.

HDPE socket fusion reducers are designed to be joined using a socket fusion process, where heat is applied to both the fitting and the pipe ends. Once heated, the fitting and pipe ends are brought together and allowed to cool, creating a strong and leak-proof connection.

The HDPE socket fusion reducer is a high-density polyethylene (HDPE) fitting used to connect pipes of different diameters and is widely used in HDPE piping systems. It employs a sleeve fusion welding process, heating the fitting and pipe ends until the required temperature is reached, then joining them together. After cooling, a strong and sealed connection is formed. This connection method not only ensures high strength and leak prevention but also provides a reliable and durable pipe connection. HDPE material has excellent corrosion resistance, chemical resistance, and high-pressure resistance, making it suitable for piping systems in various industries such as water supply, drainage, irrigation, chemical, and oil and gas. This reducer can effectively connect pipes of different sizes to meet various flow and pressure requirements. Installation is simple, requiring no complex tools; standard welding equipment is all that's needed. Furthermore, HDPE material has high temperature resistance, making it suitable for a wide range of working environments.

English

English русский

русский عربى

عربى