Advantage

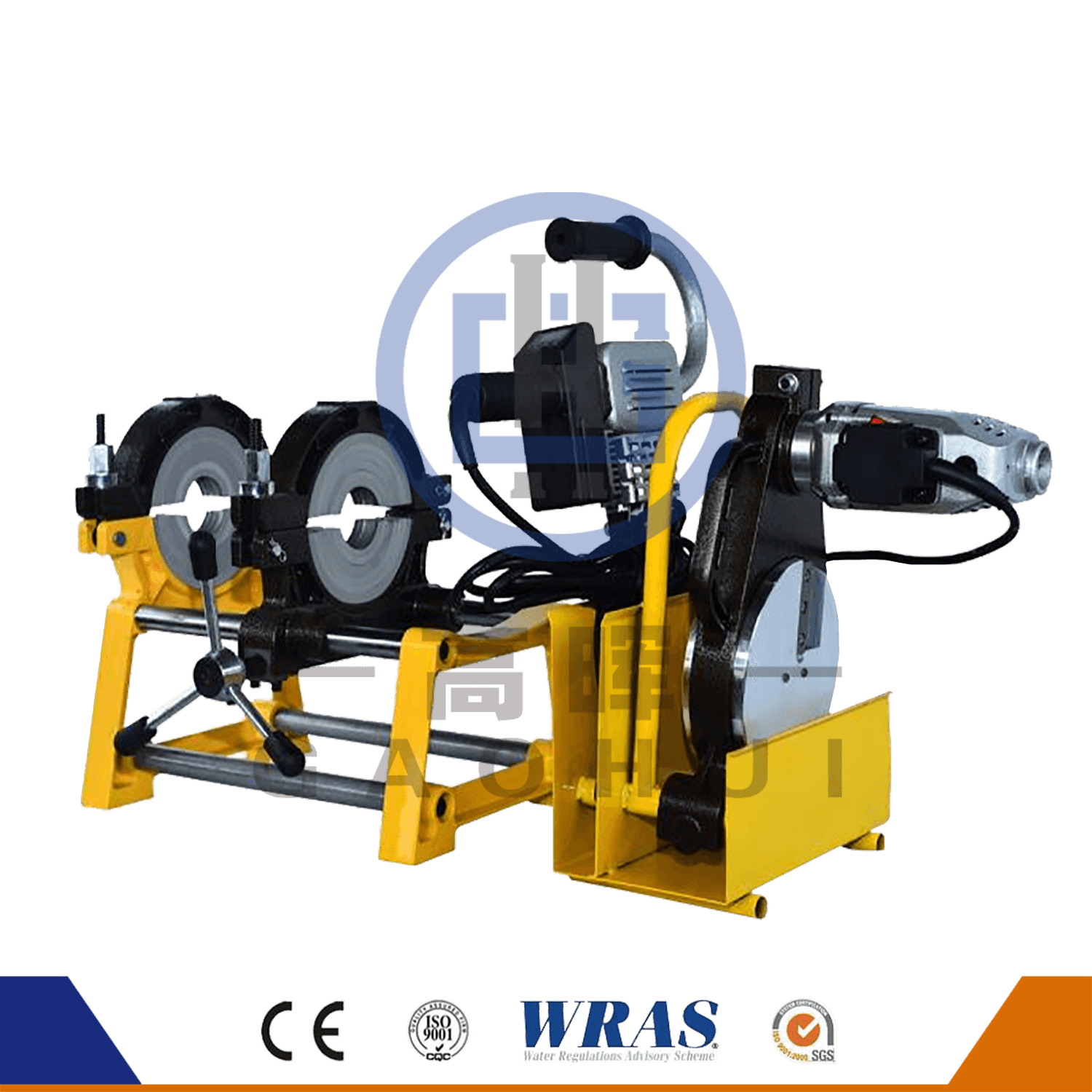

It is suitable for connecting PE, PP, PVDF pipes, pipes, and pipe fittings in construction sites and grooves;

It can also be used in the workshop;

Pure aluminum thickened frame and clamp;

High power milling cutter, rubber power cord, aluminum alloy shell;

Thicken the heating plate. Teflon paint will not stick to pipes.

The GF-I0-2M and GF-200-2M manual butt welding machines are high-efficiency devices specifically designed for butt welding of PE, PP, PVDF, and other plastic pipes and fittings. They are widely applicable to on-site operations in construction sites, pipe trenches, and workshops. The equipment utilizes a thickened pure aluminum frame and clamps to ensure structural stability, high pressure resistance, and wear resistance, enabling stable operation in high-intensity working environments. Equipped with a high-power milling cutter, the milling process is smoother and more stable, guaranteeing high-quality weld joints. Simultaneously, the equipment uses a thickened heating plate coated with Teflon to effectively prevent pipe adhesion, improve welding efficiency, and extend equipment lifespan. The outer casing is made of aluminum alloy and includes a rubber power cord, providing excellent durability and safety, and enabling it to adapt to various harsh construction environments.

English

English русский

русский عربى

عربى