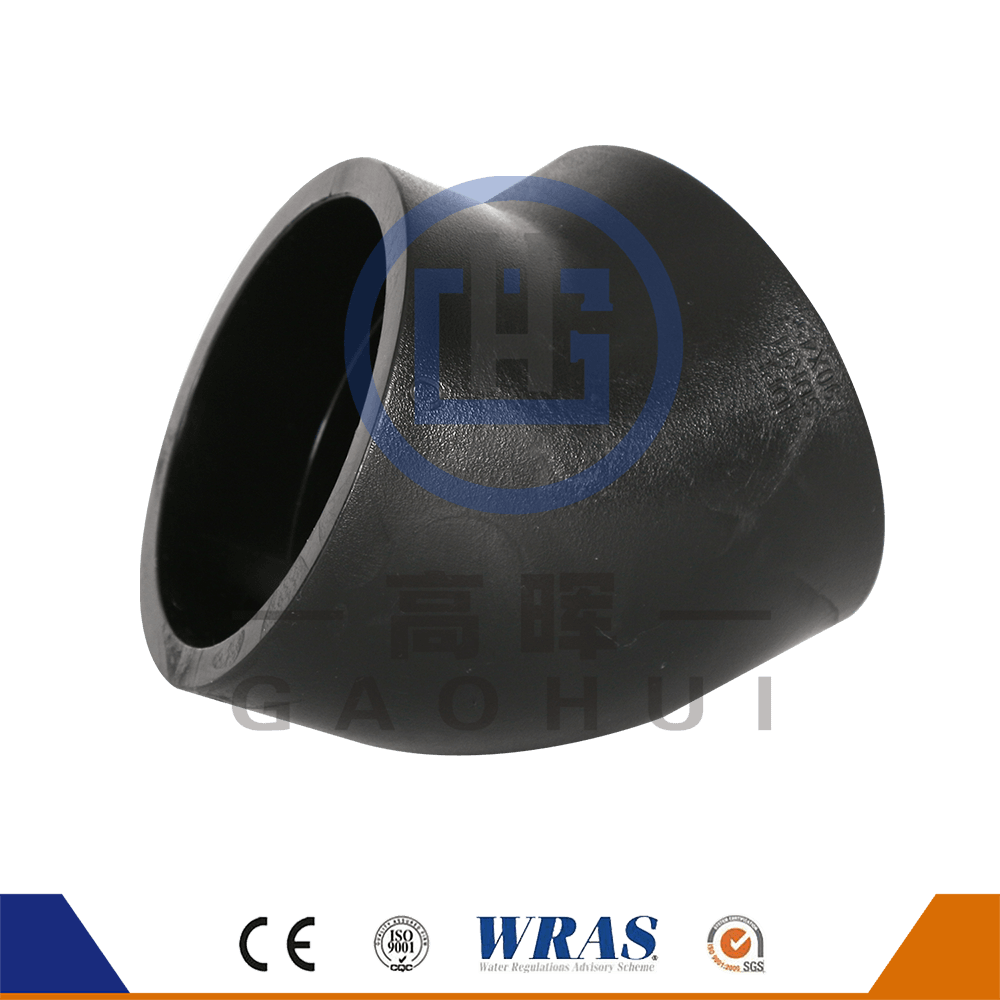

The HDPE socket fusion 45° elbow is a type of pipe fitting used in connecting High-Density Polyethylene (HDPE) pipes together at a 45-degree angle. It is designed to be fused to the pipe using a socket fusion welding technique, which involves heating the pipe and the fitting's socket with a fusion machine and then pressing them together until the material melts and forms a secure joint.

Socket fusion welding is commonly used for joining HDPE pipes in both water and gas applications because it provides a strong and leak-free connection. The 45° elbow allows for changes in direction of the pipeline while maintaining a smooth flow of fluids.

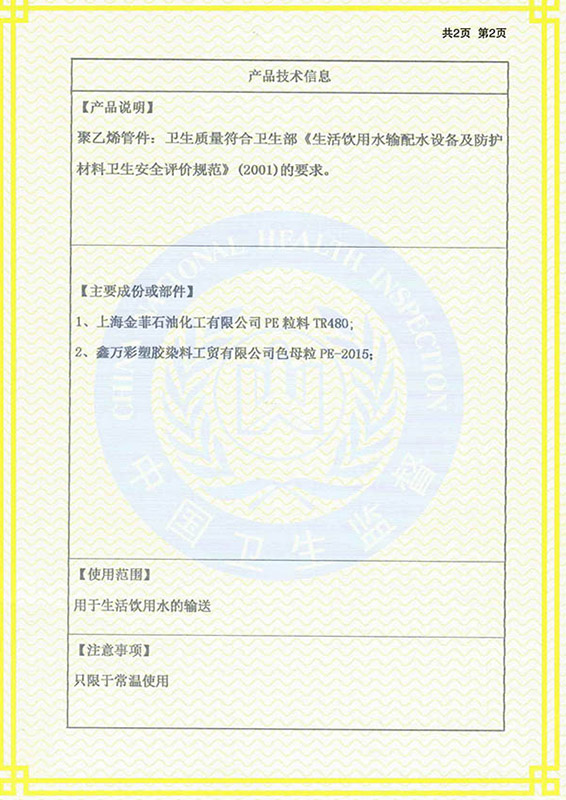

The HDPE Socket Fusion 45° Elbow is a pipe fitting made of high-density polyethylene (HDPE) material, specifically designed to facilitate smooth turns in pipelines at a 45-degree angle. The pipe and elbow are connected using socket fusion technology, where a fusion machine heats the pipe and elbow socket to create a seamless and secure connection, providing a strong and safe pipe joint. This technology is widely used in water and gas pipelines, capable of withstanding high pressure and ensuring leak-free operation. HDPE material offers excellent corrosion resistance, high temperature resistance, and impact resistance, making it suitable for various industries such as water treatment, natural gas transportation, and chemical transportation, ensuring smooth fluid flow and long-term stable system operation. The 45° elbow design reduces flow resistance, ensuring efficient fluid flow. This product is cost-effective, easy to install, has a short construction period, and is environmentally friendly and non-toxic, meeting safety and environmental standards.

English

English русский

русский عربى

عربى