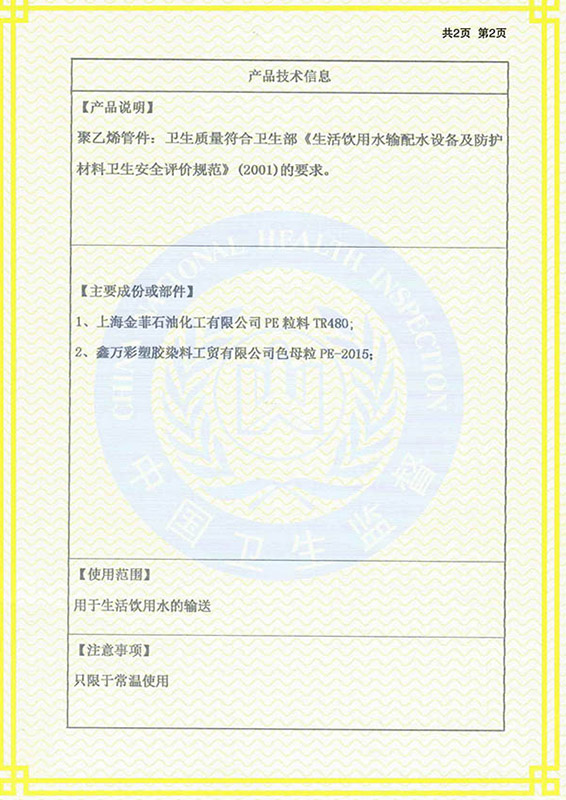

The PE pipe has high molecular weight, good stability and anti-aging ability. Under normal operating temperature, the service life of PE pipe can be guaranteed to be more than 50 years.

PE pipes do not add metal stabilizers during the processing process, and the material is non-toxic, without scaling layer, and does not breed bacteria. It is a safe and hygienic pipeline material. PE material itself can be recycled and will not produce substances that have an impact on the environment.

The molecular structure stability of PE pipes is extremely high and there is no electrochemical corrosion. Among many pipeline materials, the corrosion index of PE pipes is relatively small, and apart from a few oxidants, they can withstand corrosion from various chemical media.

PE pipe is a high toughness pipe material with a fracture elongation rate of over 500%, which has impact and earthquake resistance, and strong adaptability to uneven settlement of the pipe foundation.

HDPE pipes have good low-temperature resistance and will not exhibit brittle cracking even in extremely low environments.

HDPE pipes have flat walls and low flow resistance, resulting in fluid friction performance, not only wear resistance but also high conveying efficiency.

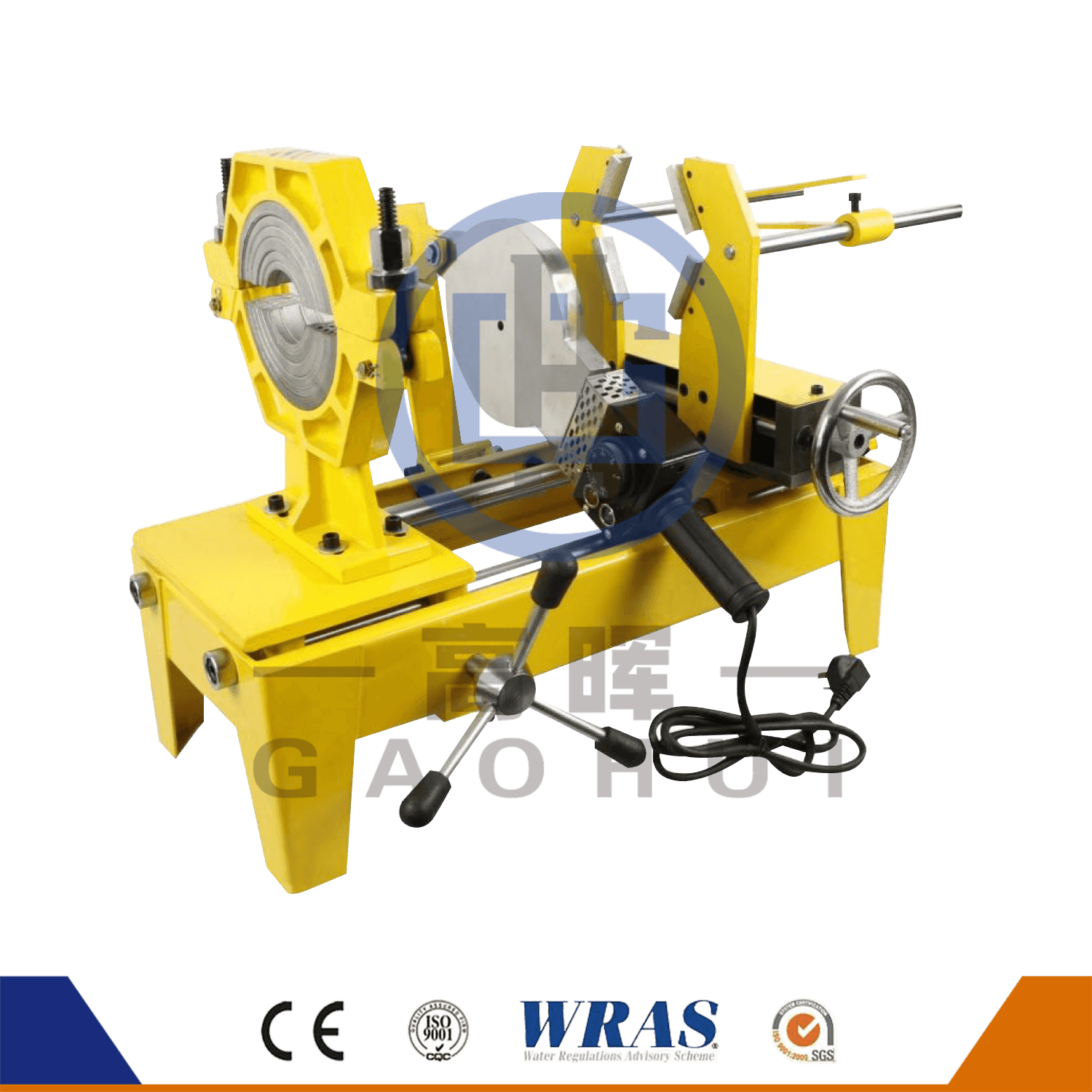

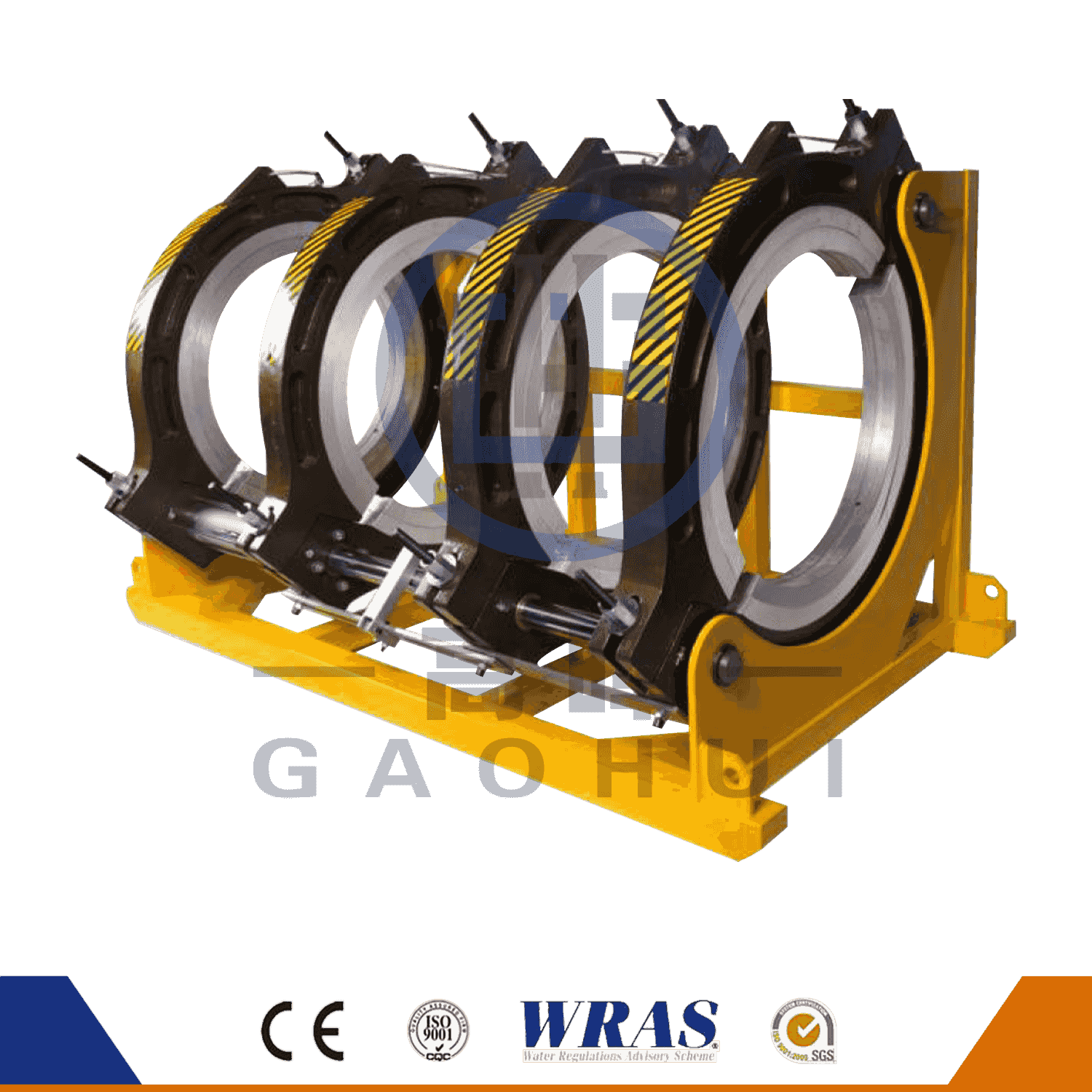

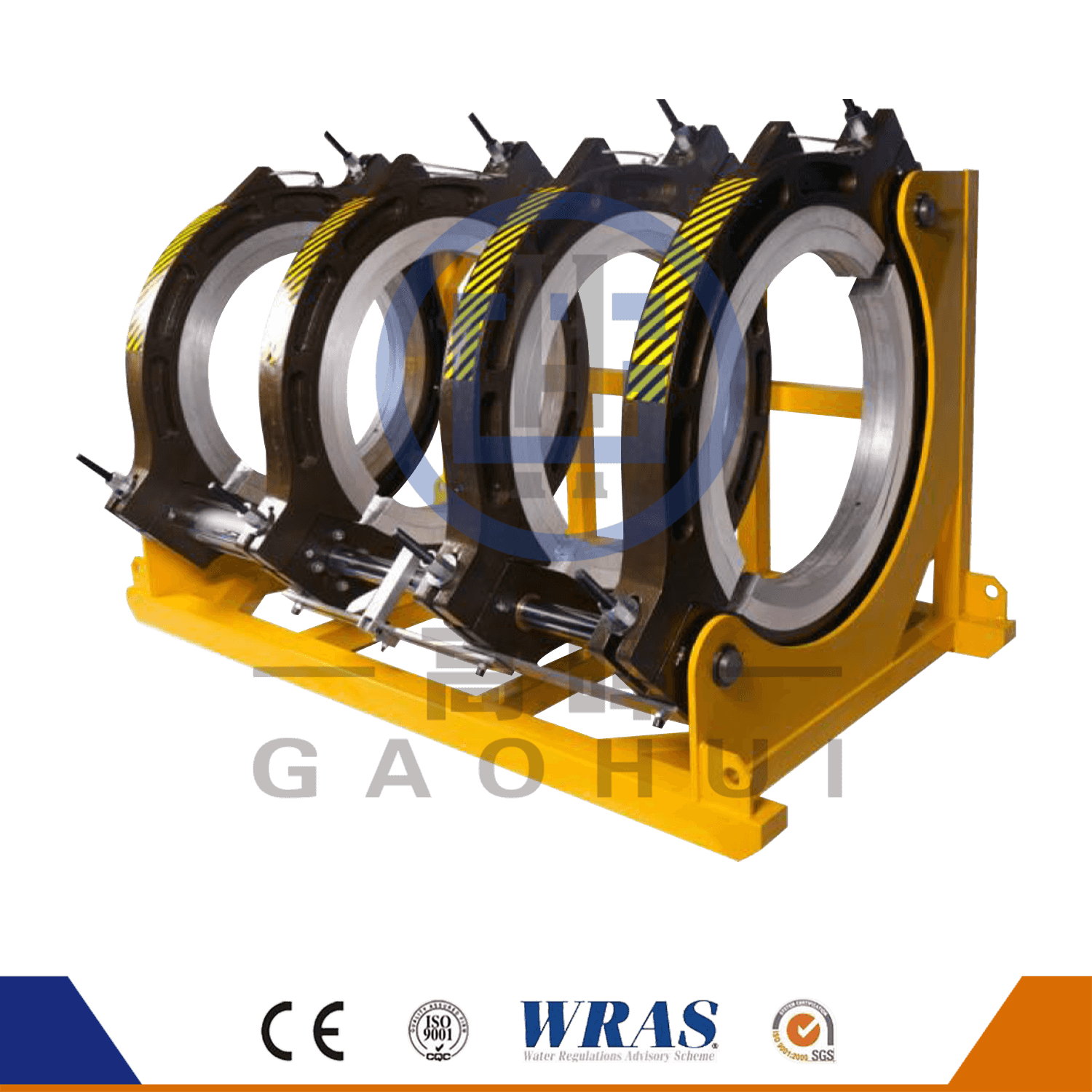

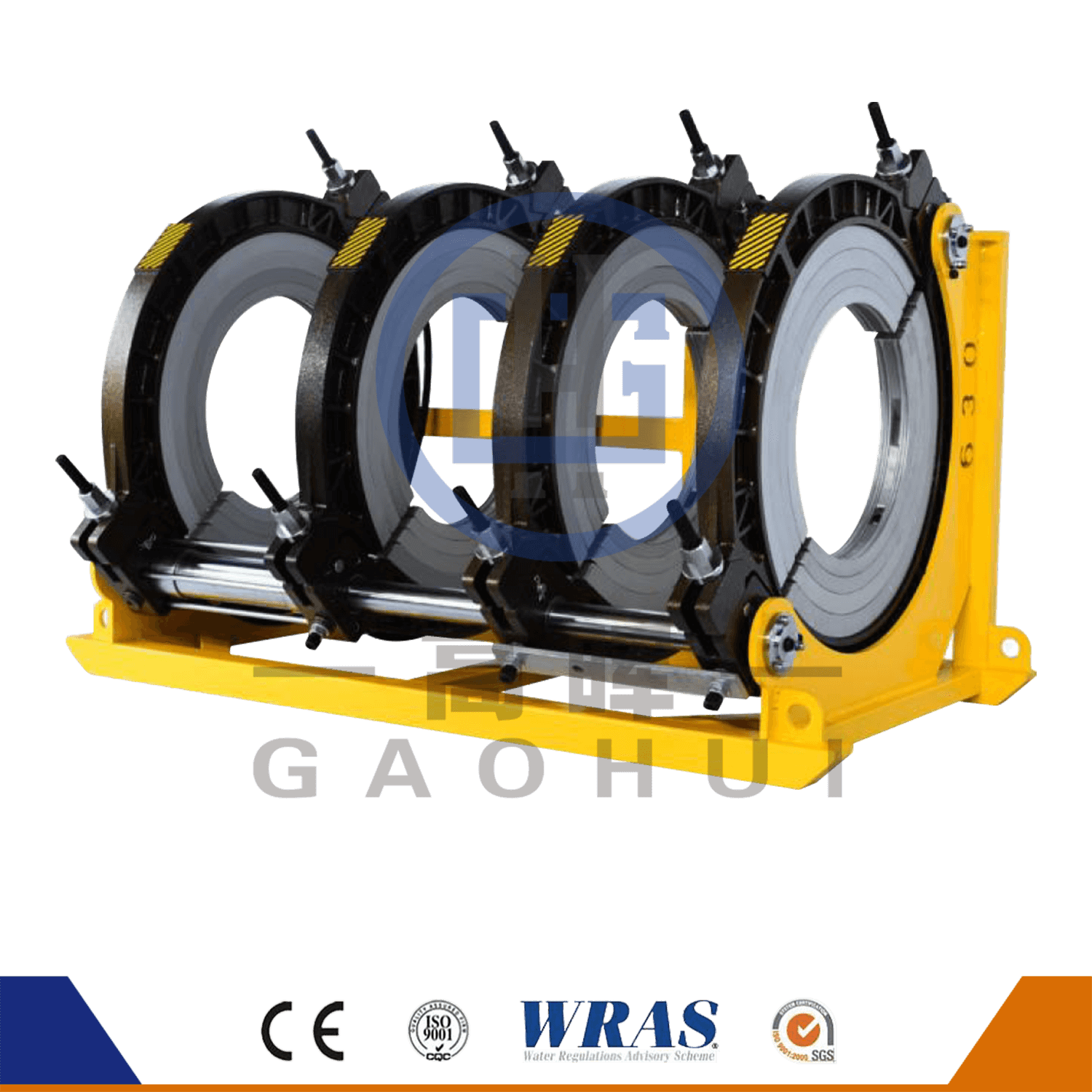

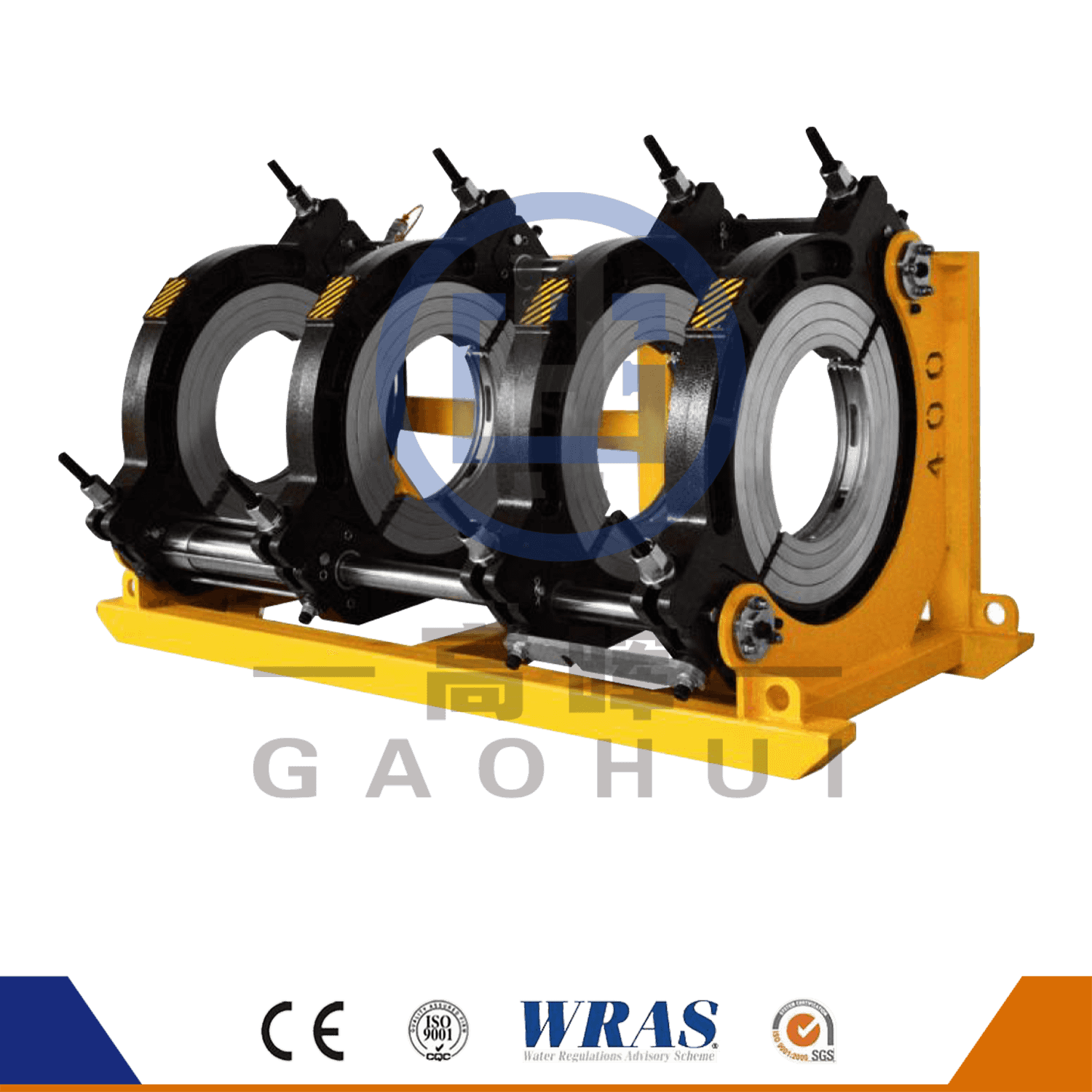

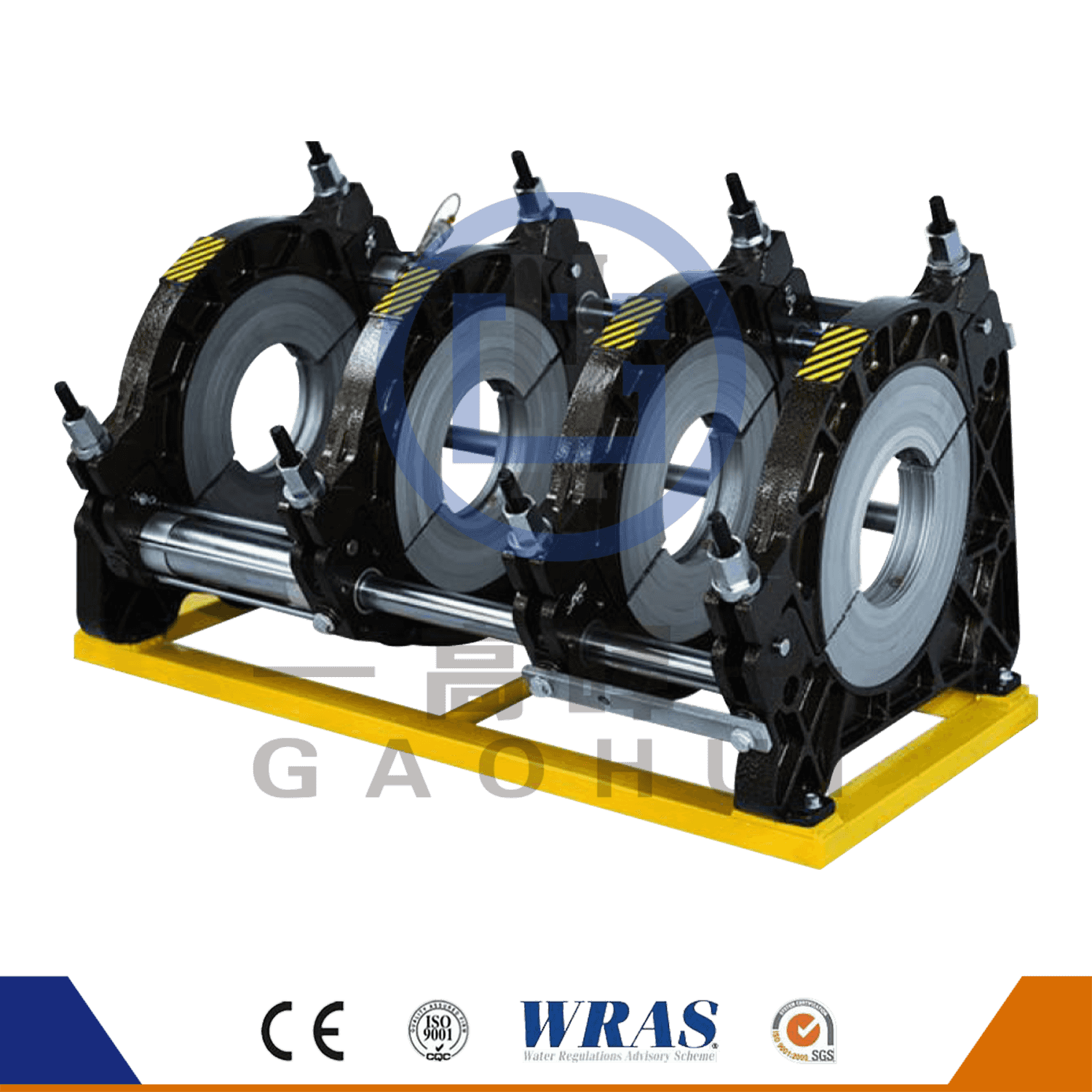

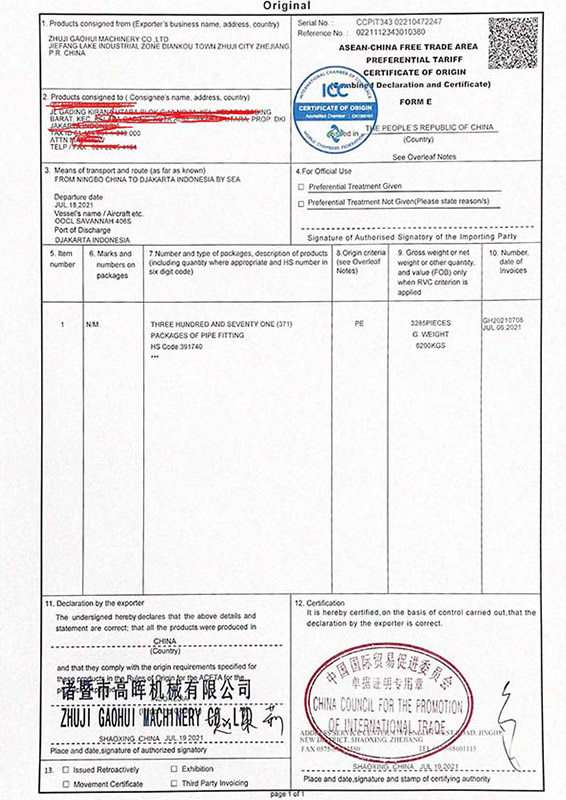

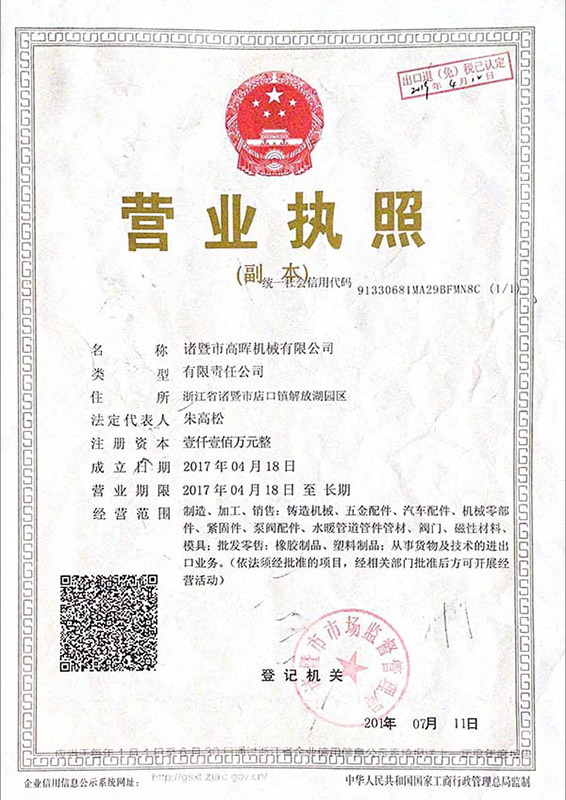

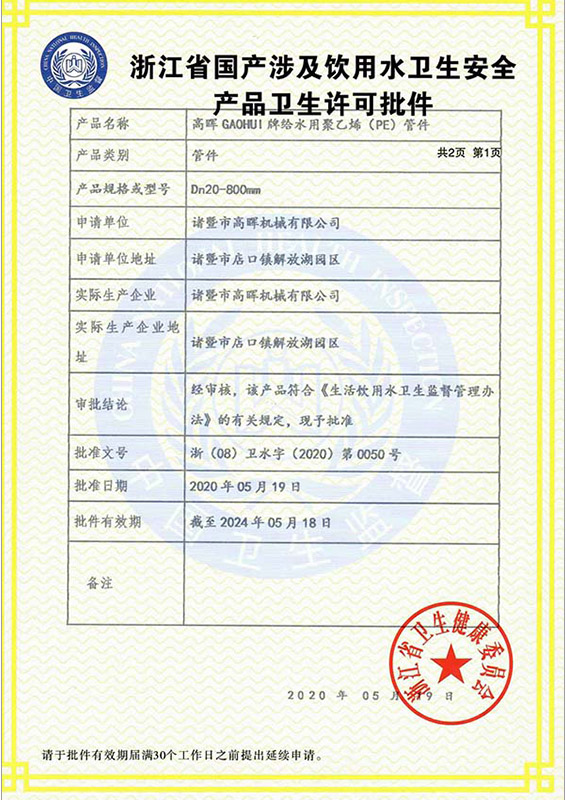

Zhuji Gaohui Machinery Co., Ltd., Gaohui is professional China Welding Machine Manufacturers and Wholesale Welding Machine Factory engaged in the research, development, production, sale, and service of Welding Machine, our main products are HDPE pipe fittings, such as electrofusion fittings, butt fusion fitting, thread fittings and etc.

We not only provide our customers with high-quality goods at factory gate prices but also provide professional pipeline application solutions. Our HDPE pipe fittings guarantee 50 years of service life in normal use. We are located in Zhuji City, Zhejiang Province, China with convenient transportation access. Delicate strict quality control and timely customer service, our experienced staff members are always available to discuss your requirements and ensure customer satisfaction. More than 50 sets of production equipment and skilled workers make sure of time delivery, we can supply HDPE fitting up to 1200mm.

In recent years, for the purpose of enlarging overseas markets, we took part in overseas exhibitions, our products are selling well in the domestic market, also our products are exported overseas, such as Netherlands, Vietnam, Philippines, Indonesia, Malaysia, Maldives, Nigeria, Thailand, Pakistan and etc., and get good reputation from customers. we also welcome ODM and OEM orders, whether selecting our current products from our catalog or seeking an engineering system for your application.

As global infrastructure continues to modernize, water supply networks and gas distribution systems are facing higher st...

View MoreIn the world of home construction and plumbing, the debate between plastic pipes and traditional materials such as coppe...

View MoreUnderground piping installations are crucial for the smooth functioning of various infrastructures, such as water distri...

View MoreWhen it comes to selecting the right fittings for your piping systems, durability is one of the most important factors t...

View MoreThe working principle of a welding machine is based on the process of melting and joining metals by passing an electric current through the welding material and generating heat. The specific principle varies depending on the type of welding machine, but generally involves an electric arc, heat generation, and the formation of a molten pool.

Arc Welding Principle:

Arc welding utilizes a high-temperature electric arc generated by passing current through the air gap between two electrodes. This arc can reach 3000-5000°C, sufficient to melt metal. The heat generated by the arc is transferred to the workpiece through the electrode (such as a welding rod) or welding wire, melting the metal and forming a welded joint. The main welding materials used in arc welding include welding rods (manual arc welding) and welding wires (MIG welding).

Key Points:

MIG Welding (Gas Metal Arc Welding) Principle:

MIG welding (Metal Inert Gas) uses a continuously fed welding wire to create an electric arc between the wire and the workpiece. During welding, the welding wire melts under the action of the arc, entering the molten pool and forming a weld. MIG welding uses an inert gas (such as argon or helium) as a shielding gas to prevent the molten pool from contacting the air, avoiding oxidation and other impurities.

Key Points:

TIG Welding (Tungsten Inert Gas Welding) Principle:

TIG welding (Tungsten Inert Gas) uses a tungsten electrode to generate an electric arc, forming a high-temperature molten pool between the electrode and the workpiece. Unlike MIG welding, TIG welding uses a non-consumable tungsten electrode, with filler material supplied by an external welding rod. The welding area is surrounded by argon or helium gas to prevent contamination from the air. TIG welding is suitable for welding thin-walled materials, precision structures, or materials requiring high quality.

Key Points:

Laser Welding Principle:

Laser welding technology uses a high-energy laser beam as a heat source, focused onto the welding location. The energy of the light heats the metal surface to its melting point. Laser welding can achieve extremely high precision and is often used for micro-welding or welding high-precision parts.

Key Points:

The design of a welding machine typically consists of several key components working together to ensure stability, precision, and safety during the welding process.

Power Source:

The power source of a welding machine provides the basic electrical power for the entire welding process. The power source needs to provide a stable voltage and current output, and its characteristics vary depending on the requirements of different welding types:

Key Points:

Transformer:

In traditional welding machines, the transformer is responsible for converting the input high-voltage, low-current electricity into a low-voltage, high-current output suitable for welding. The size and type of the transformer determine the scope of application of the welding machine.

Key Points:

Rectifier:

The function of the rectifier is to convert AC power into DC power. DC arcs are more stable and less noisy, and are therefore widely used in high-quality welding operations. The design of the rectifier has a direct impact on the performance of the welding machine, especially in industrial-grade welding.

Key Points:

Welding Torch:

The welding torch is the tool that directly contacts the welding material. Different types of welding machines have different types of welding torches:

Key Points:

Shielding Gas System (Gas Supply):

Shielding gas is a crucial part of the welding process. It protects the weld pool, preventing the molten metal from reacting with oxygen and nitrogen in the air, thus avoiding oxidation and nitridation problems. Commonly used shielding gases include argon, carbon dioxide, helium, and their mixtures.

Key Points:

At companies like Zhuji Gaohui Machinery Co., Ltd., welding machines are used not only for producing high-quality HDPE pipe fittings but also for meeting customer customization needs (such as OEM/ODM orders) and providing precise piping solutions. Proper maintenance of welding machines is crucial to ensuring product quality and timely delivery. The following are maintenance suggestions tailored to your company's specific situation:

Regular Cleaning and Inspection:

For Zhuji Gaohui Machinery Co., Ltd.'s welding machines, regular cleaning and inspection are essential. Especially when producing HDPE pipe fittings (such as electrofusion fittings, butt fusion fittings, etc.), the welding machine must be kept free of dust and impurities to avoid poor welding quality.

Specific methods:

Cable and Connector Inspection:

When producing HDPE pipe fittings, a stable power supply is essential for ensuring welding quality. Welding machine cables and connectors are prone to aging or loosening with frequent use, which can affect current stability and thus the welding quality of the pipe fittings, especially for HDPE pipe fittings that require a 50-year service life.

Specific methods:

Inspection and Replacement of Welding Torch and Electrodes:

Welding of HDPE pipe fittings requires the welding torch and electrodes to be in good condition, especially during butt fusion welding, where the welding surface must be uniform and smooth. Regularly inspect the nozzle and electrodes of the welding torch to ensure there is no carbon buildup or other contamination.

Specific methods:

Maintenance of the Cooling System:

Proper cooling is crucial when welding HDPE pipe fittings. Especially in butt fusion welding, a heating plate and cooling water system are needed to control the temperature. If the cooling system is unstable or malfunctions, it may lead to uneven welding of the pipe fittings, affecting the sealing performance and durability of the pipeline.

Specific methods:

Equipment Storage and Environmental Management:

Considering that Zhuji Gaohui Machinery Co., Ltd. has large-scale production capacity and its products are exported overseas, the storage and maintenance of the equipment also require special attention. When not in use, the welding machine should be stored in a dry, clean environment to avoid damage from moisture or excessive temperature.

Specific methods:

Quality Control in the Production Process:

With the company possessing 50 sets of production equipment and precise quality control, regular equipment inspections and quality control effectively ensure the stability of product quality. Especially in large-scale production of HDPE pipe fittings, any small welding quality problem can affect the pass rate of the entire production batch.

Specific Methods: