The PE pipe has high molecular weight, good stability and anti-aging ability. Under normal operating temperature, the service life of PE pipe can be guaranteed to be more than 50 years.

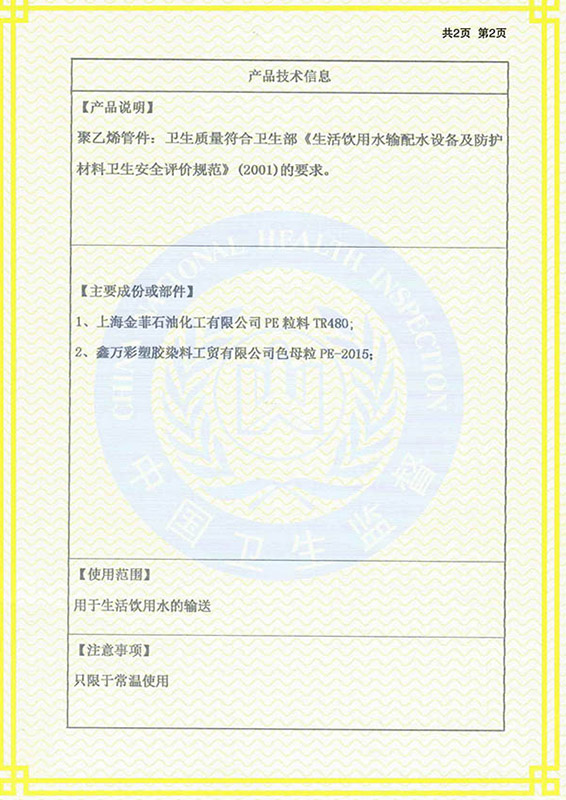

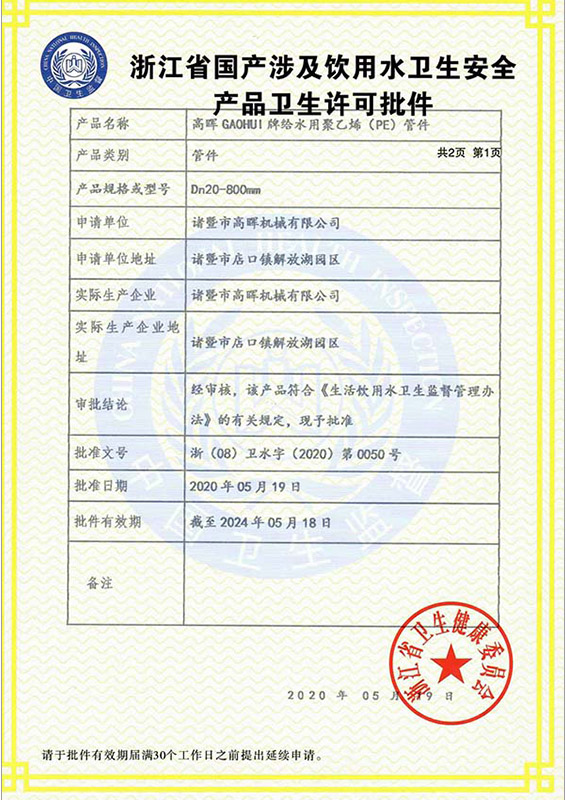

PE pipes do not add metal stabilizers during the processing process, and the material is non-toxic, without scaling layer, and does not breed bacteria. It is a safe and hygienic pipeline material. PE material itself can be recycled and will not produce substances that have an impact on the environment.

The molecular structure stability of PE pipes is extremely high and there is no electrochemical corrosion. Among many pipeline materials, the corrosion index of PE pipes is relatively small, and apart from a few oxidants, they can withstand corrosion from various chemical media.

PE pipe is a high toughness pipe material with a fracture elongation rate of over 500%, which has impact and earthquake resistance, and strong adaptability to uneven settlement of the pipe foundation.

HDPE pipes have good low-temperature resistance and will not exhibit brittle cracking even in extremely low environments.

HDPE pipes have flat walls and low flow resistance, resulting in fluid friction performance, not only wear resistance but also high conveying efficiency.

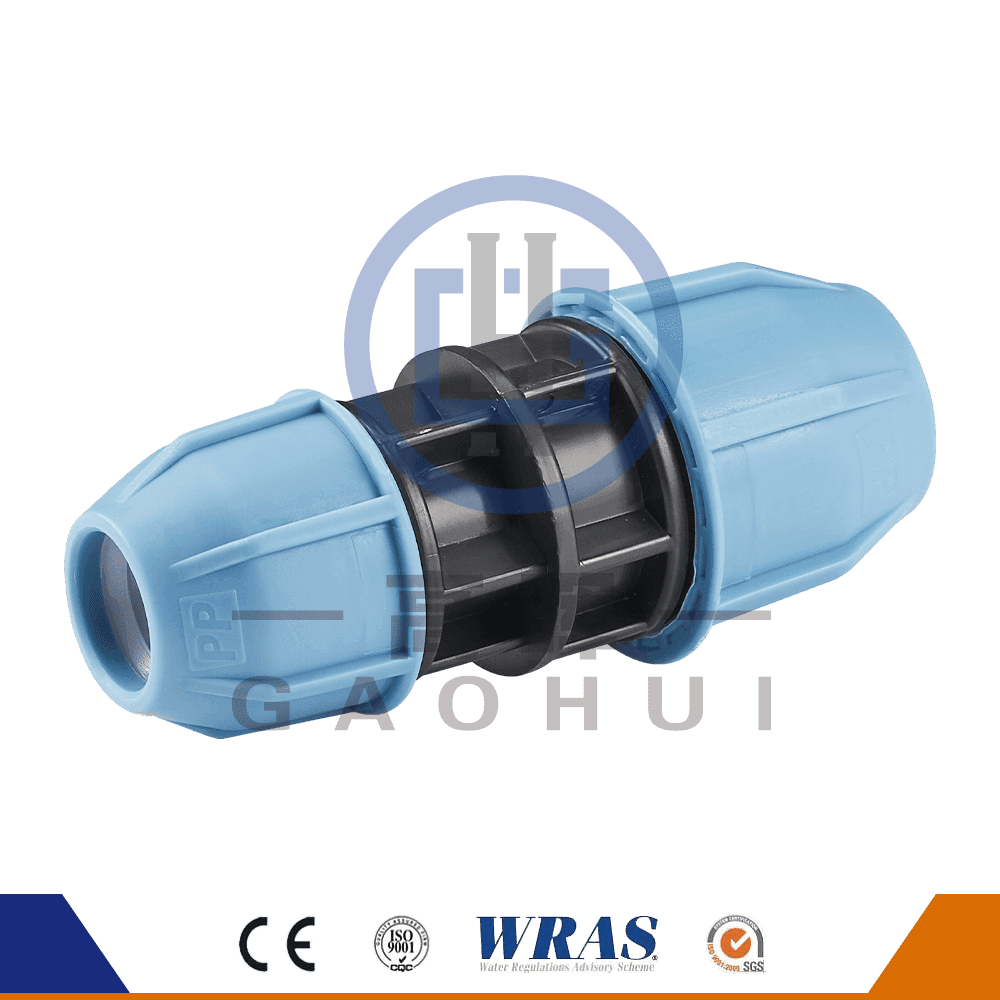

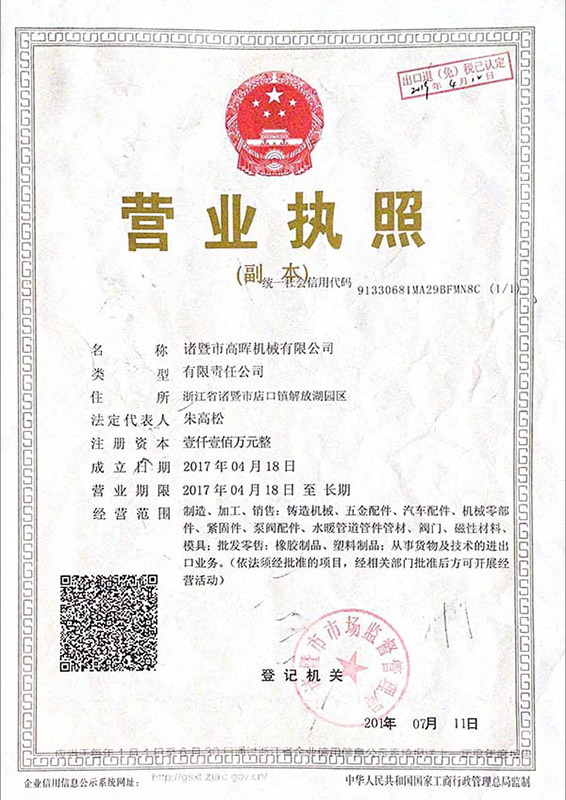

Zhuji Gaohui Machinery Co., Ltd., Gaohui is professional China PP Compression Fitting Manufacturers and Wholesale PP Compression Fitting Factory engaged in the research, development, production, sale, and service of PP Compression Fitting, our main products are HDPE pipe fittings, such as electrofusion fittings, butt fusion fitting, thread fittings and etc.

We not only provide our customers with high-quality goods at factory gate prices but also provide professional pipeline application solutions. Our HDPE pipe fittings guarantee 50 years of service life in normal use. We are located in Zhuji City, Zhejiang Province, China with convenient transportation access. Delicate strict quality control and timely customer service, our experienced staff members are always available to discuss your requirements and ensure customer satisfaction. More than 50 sets of production equipment and skilled workers make sure of time delivery, we can supply HDPE fitting up to 1200mm.

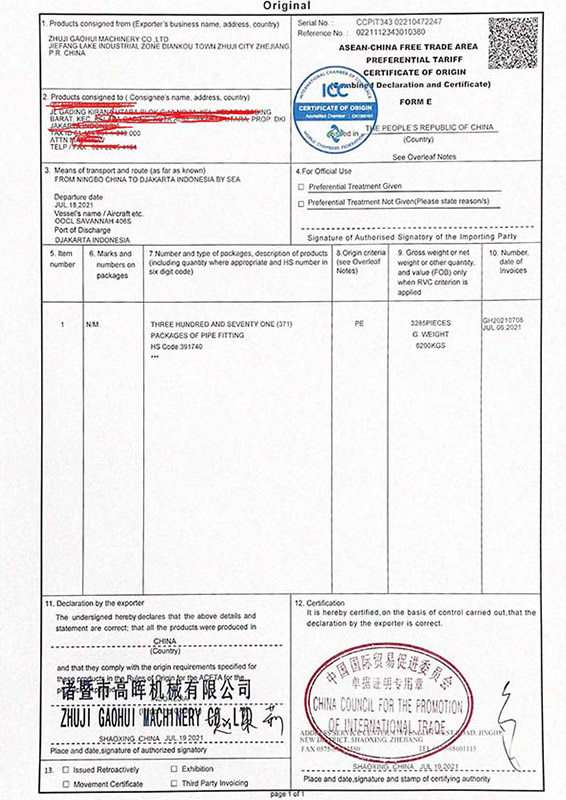

In recent years, for the purpose of enlarging overseas markets, we took part in overseas exhibitions, our products are selling well in the domestic market, also our products are exported overseas, such as Netherlands, Vietnam, Philippines, Indonesia, Malaysia, Maldives, Nigeria, Thailand, Pakistan and etc., and get good reputation from customers. we also welcome ODM and OEM orders, whether selecting our current products from our catalog or seeking an engineering system for your application.

In the world of modern pipeline infrastructure, the need for reliable, durable, and efficient systems is more critical t...

View MoreAs global infrastructure continues to modernize, water supply networks and gas distribution systems are facing higher st...

View MoreIn the world of home construction and plumbing, the debate between plastic pipes and traditional materials such as coppe...

View MoreUnderground piping installations are crucial for the smooth functioning of various infrastructures, such as water distri...

View MoreBasic Structure:

PP compression fittings have a simple yet powerful design, ensuring stable and reliable pipe connections, especially in low-pressure or medium-pressure piping systems.

Working Principle:

The working principle of PP compression fittings is based on the "compression" effect. By tightening the compression nut, the compression ring and sealing ring firmly secure the pipe within the fitting, ensuring a secure and leak-proof connection. The specific process is as follows:

Applicable Pipe Materials:

PP compression fittings are primarily used for connecting with polypropylene (PP) pipes, but they can also be used with some other types of pipe materials. The applicable pipe materials include:

Limitations of Connection Methods:

Zhuji Gaohui Machinery Co., Ltd. is a professional supplier of plastic pipes and fittings, offering a wide range of products including HDPE pipe fittings, electrofusion fittings, butt fusion fittings, and threaded fittings, while also providing professional pipeline application solutions to customers. While supplying PP compression fittings, Zhuji Gaohui Machinery Co., Ltd. also focuses on customer needs and long-term after-sales service to ensure the smooth installation and safe operation of pipeline systems.

Installation Requirements:

1. Selecting the Right Pipes and Fittings: When installing PP compression fittings, Zhuji Gaohui Machinery Co., Ltd. always emphasizes the importance of selecting fittings that match the outer diameter of the pipe. The PP compression fittings provided by Zhuji Gaohui Machinery Co., Ltd. are precisely designed to work with various PP pipes. To ensure a good connection, it is recommended to strictly follow the pipe specifications and pressure requirements when selecting the appropriate fittings.

Professional Support from Zhuji Gaohui Machinery Co., Ltd.:

2. Pipe End Preparation: Before installation, it is essential to ensure that the pipe ends are cut cleanly and free of burrs. The fittings produced by Zhuji Gaohui Machinery Co., Ltd. utilize precise manufacturing processes to ensure that the pipe interfaces are smooth and suitable for a tight fit. Any uneven cuts or rough pipe surfaces may affect the installation of the compression fittings and lead to leaks. Quality Control at Zhuji Gaohui Machinery Co., Ltd.:

3. Cleaning the Pipes: Before installation, Zhuji Gaohui Machinery Co., Ltd. recommends ensuring that the pipe ends and surrounding areas are free of oil, dust, or impurities. These substances may affect the compression effect of the sealing ring, leading to loose connections or leaks. Zhuji Gaohui Machinery Co., Ltd. specifically recommends using high-standard cleaning methods to ensure a perfect fit for every part.

Installation Sequence:

The PP compression fittings provided by Zhuji Gaohui Machinery Co., Ltd. require a strict set of steps during installation to ensure reliable connection and sealing:

Precautions:

1. Avoid Overtightening the Nut: During installation, Zhuji Gaohui Machinery Co., Ltd. specifically reminds customers to avoid using excessive force to tighten the compression nut. Overtightening will not enhance the connection effect; instead, it may damage the sealing ring and cause pipe leakage. It is recommended to use appropriate tools to avoid overtightening and ensure sealing performance.

2. Test the Connection: After installation, a water pressure test is recommended. Zhuji Gaohui Machinery Co., Ltd.'s pipe fittings are rigorously tested to provide stable performance in a variety of piping environments. However, a hydrostatic pressure test is still required to confirm the absence of any leaks. Zhuji Gaohui Machinery Co., Ltd. strictly adheres to quality standards during the manufacturing process, and all products undergo rigorous quality inspections before leaving the factory to ensure secure connections.

3. Avoid Pressure Surges: During installation and use, Zhuji Gaohui Machinery Co., Ltd. emphasizes avoiding pressure fluctuations or pressure surges in the piping system, which can damage connection points and lead to leaks or other malfunctions. Zhuji Gaohui Machinery Co., Ltd. recommends using pressure regulating devices to ensure the stability of the piping system during long-term use.

4. Environmental Conditions:

5. Long-Term Maintenance and Inspection: Although PP compression fittings have low maintenance costs, Zhuji Gaohui Machinery Co., Ltd. recommends regular inspections of the piping system. Regularly checking the tightness, sealing, and pressure resistance of the pipes can effectively prevent problems such as pipe leaks and improve the overall efficiency of the system.

Zhuji Gaohui Machinery Co., Ltd.'s After-Sales Service and Support: Zhuji Gaohui Machinery Co., Ltd. not only provides high-quality products but also offers customers professional piping application solutions. Whether for OEM or ODM requirements, Zhuji Gaohui Machinery Co., Ltd.'s technical team can provide customized services according to customers' specific needs, ensuring superior performance of piping systems in various applications. Furthermore, Zhuji Gaohui Machinery Co., Ltd. is committed to providing customers with timely after-sales service, addressing any issues encountered during installation or maintenance.