What is the working principle of an electrofusion machine? How does it achieve pipe connection?

The working principle of an electrofusion machine is based on the conversion of electrical energy into heat energy. It heats the electrofusion fitting using resistance wires, causing it to fuse with the pipe surface, forming a strong connection.

Fitting Design and Preparation

- Electrofusion Fitting Design: Electrofusion fittings typically consist of two parts: an outer plastic material that contacts the pipe, and an inner part containing resistance wires (or heating wires). The design and layout of these resistance wires are crucial, as their number and arrangement directly affect the uniformity of heating.

- Pipe Preparation: Before connecting the electrofusion fitting, both ends of the pipe need to be cut, cleaned, and trimmed. The cut surface must be flat and free of burrs to ensure that the fitting makes full contact with the pipe surface, enhancing the fusion effect.

- Cleaning: Cleaning is key to ensuring connection quality. The pipe surface must be free of oil, dirt, and moisture. Any impurities can affect the fusion quality, leading to a weak connection or leaks.

Heating Process

- Current Application: After the electrofusion machine is started, it transmits current to the resistance wires inside the fitting via cables. The current magnitude and heating time are precisely controlled based on the pipe material, size, and fitting type.

- Heat Generation: The resistance wires have high resistance, generating a large amount of heat when current passes through them. This heat is quickly transferred to the fitting and pipe surface, causing the plastic material to soften and melt.

- Temperature Control: The temperature control system within the electrofusion machine automatically adjusts the heating time and current to ensure that the pipe and fitting reach the optimal melting temperature. This temperature is typically between 200°C and 260°C, depending on the type of pipe material (for example, the melting temperature of PE pipes is generally 220°C).

Fusion and Cooling

- Fusion: Once the temperature reaches the set value, the fitting and pipe surface quickly fuse together. The melted plastic fills the gaps in the fitting and forms a strong molecular structure, creating a permanent bond between the fitting and the pipe.

- Cooling: After the heating process is complete, the electrofusion machine automatically shuts off the power and enters the cooling phase. At this time, the melted parts of the joint and pipe begin to solidify, forming a strong connection. The cooling time is also crucial; too rapid cooling may result in insufficient joint strength, while too slow cooling may prolong construction time.

Connection Strength and Stability

- Strength of the Fusion Connection: The connections formed by electrofusion joints can generally withstand considerable internal pressure and external forces, and are therefore often used in high-pressure piping systems. Because the molecular structure of the fusion area is similar to the atomic structure of the pipe material, it forms physical properties similar to the pipe itself.

- Connection Stability: One of the advantages of electrofusion technology is the stability of the connection. The corrosion resistance and high-temperature resistance of the fusion zone ensure a long service life in various environments.

In which fields are Electrofusion Machines primarily used?

Due to their efficiency, precision, and reliability, Electrofusion Machines are widely used in the following fields:

Natural Gas Pipelines

- Applicable Pipe Materials: Electrofusion welding is widely used in natural gas pipelines, especially PE (polyethylene) pipes, because polyethylene has excellent corrosion resistance and low-temperature resistance, making it suitable for underground burial and natural gas transportation.

- Pipeline Installation: During natural gas pipeline construction, electrofusion technology ensures the sealing of joints, preventing gas leaks. On-site, the fast and convenient operation of the Electrofusion Machine shortens construction time and improves project efficiency.

- High Pressure Resistance: Electrofusion joints can withstand high internal pressure, making them particularly important in long-distance, high-pressure natural gas pipelines.

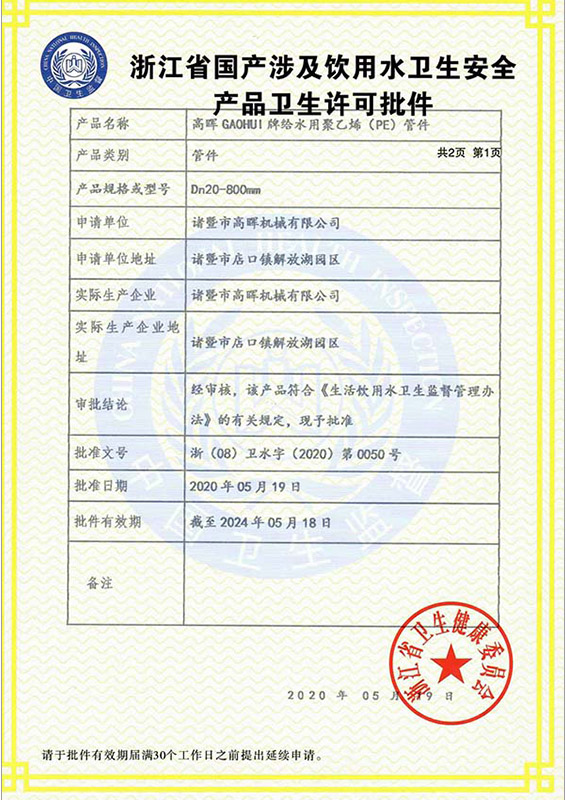

Water Supply Systems

- Urban Water Supply: In urban water supply systems, electrofusion technology is used for PE pipe connections, providing an efficient and reliable water supply pipeline system. Since water flow typically does not involve extreme temperature or pressure changes, electrofusion connections provide long-term stability.

- Corrosion Resistance: Water supply pipelines are often exposed to various external environments. The corrosion resistance of electrofusion connections ensures the durability of the pipeline system, especially in areas with severe chemical corrosion.

Oil Pipelines

- High-Strength Connections: Oil pipelines need to withstand very high pressures when transporting crude oil or natural gas, and the connection strength provided by electrofusion joints meets this requirement. Especially in long-distance oil transportation, electrofusion joints not only improve construction efficiency but also reduce the risk of joint leakage.

- High Temperature and Pressure Resistance: Oil pipelines typically experience high temperature and high-pressure environments, and the electrofusion welding process ensures that the pipe connections maintain good performance under these extreme conditions.

Power and Communication Pipelines

- Underground Cable Protection: The power industry uses electrofusion connections to protect cables in pipelines. These pipelines typically need to withstand various external pressures, chemical corrosion, and weather changes.

- Communication Fiber Optics: For protective conduits of communication fiber optics, electrofusion joints not only ensure secure connections but also prevent signal interference caused by environmental factors.

Subsea Pipelines

- Offshore Oil and Gas Extraction: In offshore oil and gas extraction, electrofusion-connected pipelines are particularly suitable for subsea pipeline systems due to their excellent corrosion resistance. Electrofusion joints maintain stable performance in harsh marine environments, preventing leaks.

- Subsea Communication and Power Transmission: Subsea communication and power transmission pipelines also utilize electrofusion connection technology to ensure long-term stable service.

Industrial Manufacturing and Chemical Pipelines

- Chemical Corrosion Resistance: In chemical plants or other industrial production processes, pipelines often need to resist corrosion from various chemical substances. The sealing and corrosion resistance provided by electrofusion joints ensure the long-term stable operation of the pipeline system.

- High Temperature and High Pressure Pipelines: For industrial pipelines that need to withstand high temperatures or high pressures, electrofusion joints provide stable connection strength, preventing pipeline leaks or ruptures.

What safety precautions should operators take when using the electrofusion machine?

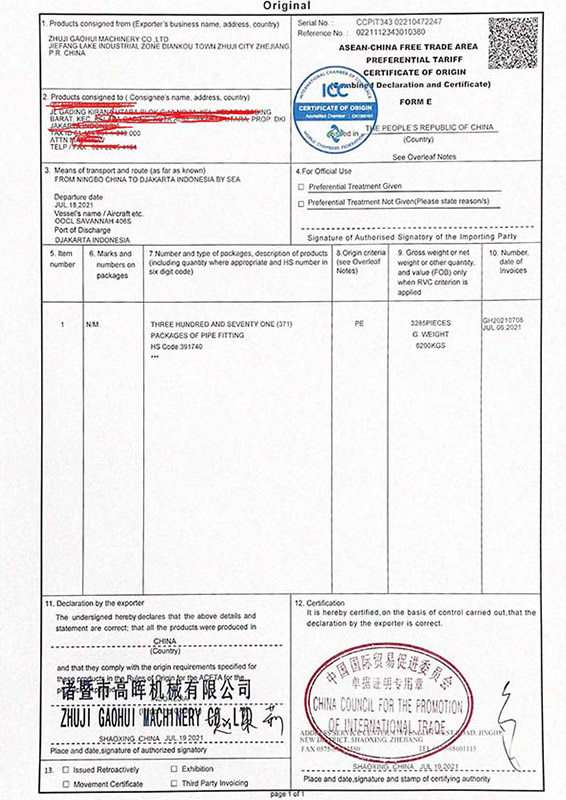

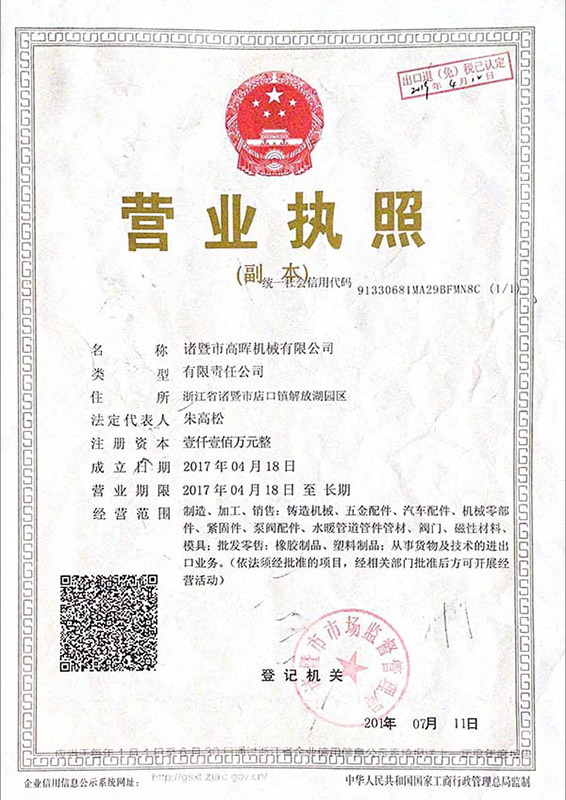

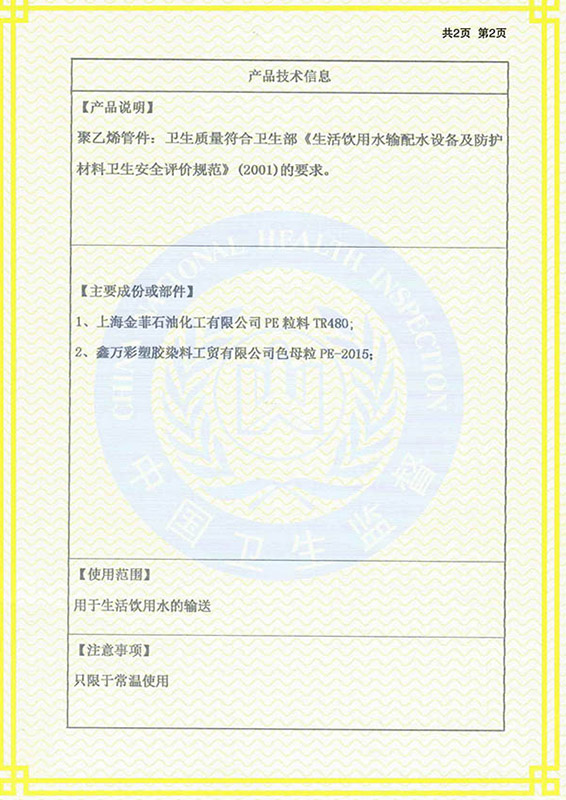

At Zhuji Gaohui Machinery Co., Ltd., ensuring operational safety is a crucial part of the manufacturing process, especially during the use of Electrofusion Machines. As a company specializing in the research, development, production, sales, and service of plastic pipes and fittings, Zhuji Gaohui Machinery Co., Ltd. understands the importance of safe operation for the long-term stability and lifespan of piping systems. Zhuji Gaohui Machinery Co., Ltd.'s products, such as HDPE pipe fittings (including electrofusion fittings, socket fusion fittings, threaded fittings, etc.), are designed with both ease of operation and safety in mind. The products we provide to our customers not only meet international quality standards but also strive to ensure safety and reliability during the construction process.

High Temperature Hazards

Electrofusion Machines convert electrical energy into heat, heating the pipe ends through electrofusion fittings. Due to the high-temperature operation involved, operators need to pay extra attention to the following points:

- Operator Protection: To protect operators from high-temperature injuries, Zhuji Gaohui Machinery Co., Ltd. recommends wearing protective gloves, heat-resistant work clothes, and safety glasses when using the Electrofusion Machine. These protective gears not only prevent burns but also protect the eyes from high-temperature steam or molten plastic.

- Avoid Contact with Heating Components: The heating area of the Electrofusion Machine can reach over 220°C, and operators should avoid direct contact with the heating components. To avoid high-temperature burns, operate cautiously and ensure that other personnel are kept away from the heating area.

- Safe Operating Environment: Zhuji Gaohui Machinery Co., Ltd.'s products undergo strict quality control to ensure that the equipment meets international safety standards. At the construction site, operators should ensure that there are no flammable materials nearby to prevent fires caused by the melting of electrofusion fittings.

Electrical Safety

Electrofusion Machines use electricity for heating, and electrical safety is one of the core elements to ensure operator safety. As a supplier of high-quality pipe fittings and solutions, Zhuji Gaohui Machinery Co., Ltd. focuses on safety in its electrical design.

- Power Cord and Grounding: When using the Electrofusion Machine, operators must ensure that the power cord is intact and properly grounded. If the electrical equipment is not properly grounded, it may lead to electric shock accidents. Electrofusion The electrical components of the machine require regular inspection to ensure secure electrical connections and prevent short circuits caused by aging wiring or poor contact.

- Use of Standard-Compliant Electrical Components: Zhuji Gaohui Machinery Co., Ltd. uses electrical components and accessories that comply with international safety standards. During use, operators should regularly inspect the electrical system to ensure that electrical components are undamaged, preventing fires or electric shock accidents caused by electrical faults.

- Emergency Handling of Electrical Faults: In the event of an electrical fault, the operator should immediately cut off the power supply and take measures according to the emergency handling guidelines. If a fire occurs, the operator should use a CO₂ fire extinguisher to extinguish the fire. Water should not be used for electrical fires to avoid exacerbating the accident.

Pipe Installation and Connection Safety

Ensuring the quality and safety of pipe connections is crucial, especially with HDPE pipe fittings provided by Zhuji Gaohui Machinery Co., Ltd., where ensuring a perfect fit between the pipe and fittings is essential.

- Joint Alignment and Cleaning: Before electrofusion welding, the end faces of the pipe joints must be clean and flat. The electrofusion fittings provided by Zhuji Gaohui Machinery Co., Ltd. are designed with this in mind, ensuring good fit and contact. Operators should inspect the joint end faces during installation to ensure there is no oil, impurities, or unevenness that could affect the connection quality.

- Pipe Support: During electrofusion welding, the pipe must be properly supported to prevent displacement or bending during the heating process. Zhuji Gaohui Machinery Co., Ltd.'s fittings are carefully designed to ensure a secure and reliable connection between the pipe and fittings under normal operating conditions.

- Installation Process Monitoring: During installation, operators should constantly monitor the temperature and current parameters of the Electrofusion Machine to ensure that the heating process meets the requirements. Zhuji Gaohui Machinery Co., Ltd.'s electrofusion fittings usually come with specific parameter specifications to ensure that every aspect of the pipe connection is strictly controlled.

Equipment Operation and Monitoring

Zhuji Gaohui Machinery Co., Ltd. not only provides high-quality products but also professional technical support and services. The operation and monitoring of the Electrofusion Machine are key to ensuring that each connection is successful.

- Strictly Follow Operating Procedures: Electrofusion The operation of the machine must strictly adhere to the operating manual provided by the manufacturer. Operators need to set appropriate current, temperature, and heating time during the installation process to avoid insecure connections due to improper parameter settings. Zhuji Gaohui Machinery Co., Ltd. provides specific parameter guidance based on different pipe and joint sizes, helping operators quickly set up and complete the operation.

- Monitoring System and Data Recording: Some electrofusion machines are equipped with real-time monitoring systems that can monitor key parameters such as temperature, current, and heating time. This equipment not only ensures connection quality but also alerts operators to make timely adjustments in case of abnormalities. Zhuji Gaohui Machinery Co., Ltd.'s accessories and piping system solutions are usually compatible with these intelligent monitoring systems, ensuring accurate data and comprehensive control of the construction process.

Emergency Handling and Operator Training

To cope with various emergencies during the operation of the electrofusion machine, Zhuji Gaohui Machinery Co., Ltd. emphasizes that operators must receive necessary training and safety drills.

- Operator Training: As a company with over 50 production machines and a strong focus on quality control, Zhuji Gaohui Machinery Co., Ltd. provides customers with detailed product user manuals and operating instructions, and regularly organizes operator training to ensure that construction personnel master the correct operating skills and reduce safety hazards caused by operating errors.

- Emergency Handling Guidelines: Operators should be familiar with emergency handling procedures and practice them in their daily work. For example, in case of equipment failure, operators should immediately cut off the power and troubleshoot the problem to prevent the accident from escalating. Zhuji Gaohui Machinery Co., Ltd. recommends that all operators understand the common types of equipment failures and emergency response procedures to ensure that problems can be solved quickly and effectively in case of abnormalities.