Basic Characteristics of HDPE Tubes

Material Introduction

HDPE (High-Density Polyethylene) is a highly crystalline thermoplastic polymer. It is polymerized from ethylene monomers and has a linear molecular structure. This structure gives HDPE its high crystallinity and density (typically 0.93 g/cm³ to 0.97 g/cm³). The high crystallinity of HDPE results in superior physical properties, particularly in terms of wear resistance, tensile strength, and compressive strength.

- Molecular Structure: HDPE molecules have a relatively simple chain structure with few branches, resulting in higher mechanical strength.

- Applications: HDPE is widely used in the production of various pipes, containers, bottles, and other products, especially in environments requiring high strength and chemical resistance.

Advantages

- Corrosion Resistance: HDPE tubes effectively resist corrosion from most chemical substances. They exhibit good resistance to common chemical solvents, acids, bases, and salts. HDPE tubes are a preferred material in petrochemicals, agricultural irrigation, and wastewater treatment.

- Example: In agricultural irrigation systems, HDPE tubes resist corrosion from fertilizers and pesticide solutions, significantly extending their service life.

- UV Resistance: HDPE itself has some resistance to UV radiation, but prolonged exposure to sunlight can lead to material degradation. Therefore, HDPE tubes are usually treated with UV stabilizers.

- UV Stability: By adding UV stabilizers (such as carbon black) during the manufacturing process, the UV resistance of HDPE tubes can be enhanced, making them suitable for outdoor piping systems (such as urban water supply and drainage pipes).

- High Strength: HDPE tubes have high tensile and compressive strength, allowing them to be used under high pressure without easily cracking or deforming.

- Compressive Strength: For example, a DN100 (100mm outer diameter) HDPE tube typically has a compressive strength of 10-16 MPa, suitable for high-pressure environments.

- High and Low Temperature Resistance: HDPE tubes can withstand temperatures ranging from -40°C to +60°C, but they become brittle at extremely low temperatures (below -50°C). The temperature resistance range of different HDPE tube products can be modified as needed; for example, low-temperature resistant and anti-brittle HDPE tubes can withstand even lower temperatures.

- Lightweight: Compared to traditional pipes such as steel and cast iron pipes, HDPE tubes are lightweight and easy to install. Due to their lightweight nature, they can effectively reduce transportation costs and improve construction efficiency. Installation can be completed manually or with small machinery, without the need for large heavy equipment.

Disadvantages

- Easy to Scratch: The surface of HDPE tubes is relatively soft and easily scratched by sharp objects, especially during installation and transportation. Scratches may affect their sealing performance, leading to water leakage or other leaks.

- Solutions: Protective measures should be taken during transportation and storage, such as using scratch-resistant packaging materials. In addition, some HDPE tube products with reinforced surfaces (such as wear-resistant HDPE tubes) can better resist this problem.

- Low-Temperature Brittleness: Although HDPE tubes have strong low-temperature resistance, they may become brittle and fracture in extremely low-temperature environments. This requires special attention when used in cold northern regions.

- Modification: To address this issue, some HDPE tubes use modified materials (such as reinforced polymers or added low-temperature resistant agents) to improve their low-temperature toughness.

- Susceptible to Environmental Stress Cracking: HDPE tubes that are subjected to long-term stress or are at high stress concentration points may experience environmental stress cracking (ESC). This is especially true if there are defects or improper handling of the pipe surface, which can accelerate crack formation.

- Preventive Measures: Selecting appropriate pipe wall thickness, avoiding high stress concentrations, and conducting regular pipe inspections are recommended.

Production and Processing of HDPE Tubes

Raw Material Preparation

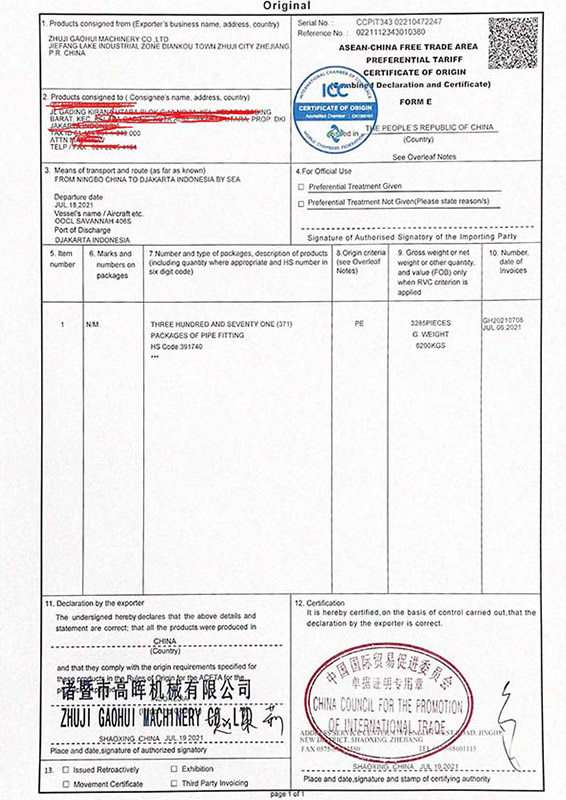

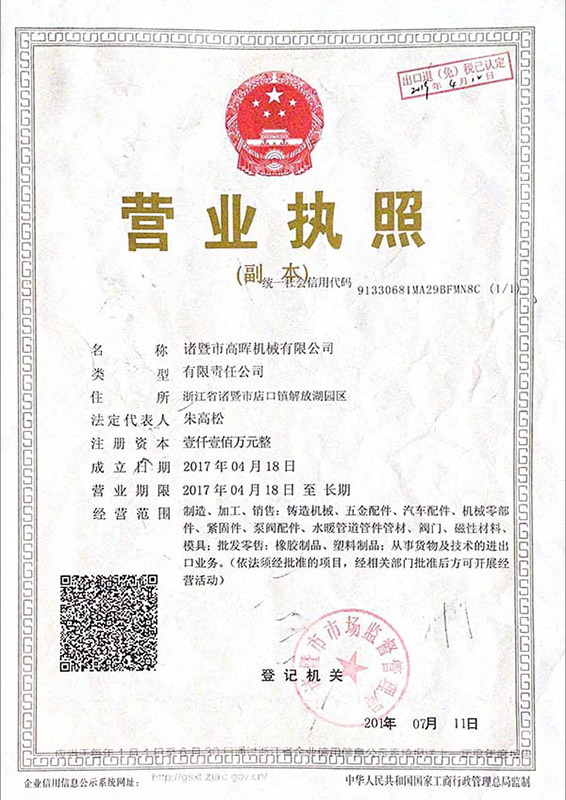

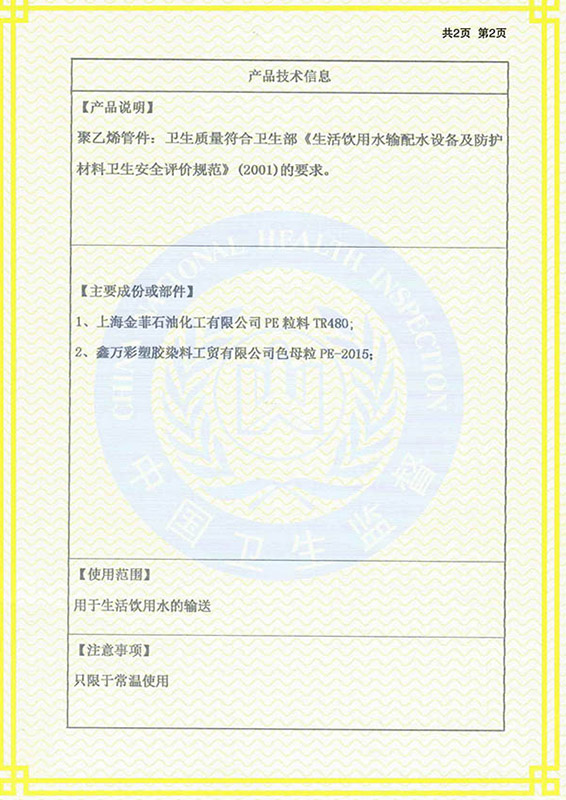

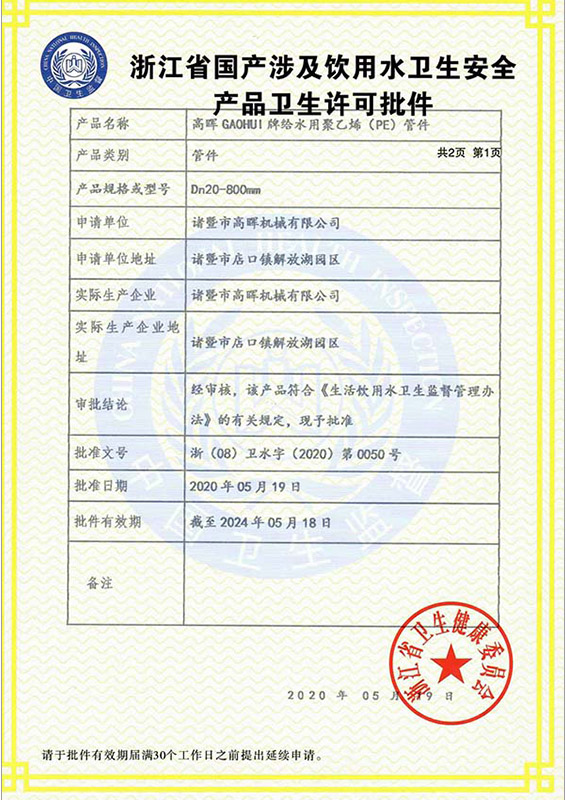

For Zhuji Gaohui Machinery Co., Ltd., the production of HDPE pipe fittings begins with the selection of high-quality raw materials. The company consistently uses high-quality HDPE resin to ensure the durability and reliability of its pipes and fittings. To guarantee the long-term performance of the pipe fittings, Zhuji Gaohui Machinery Co., Ltd. maintains long-term cooperative relationships with globally renowned raw material suppliers to ensure a stable supply of materials and provides different types of HDPE raw materials, such as PE100 and PE80, to meet the needs of different customers.

- Strict Raw Material Screening: The PE resin selected by Zhuji Gaohui Machinery Co., Ltd. complies with international standards (such as ISO 4427) to ensure high strength, high toughness, and good chemical resistance of the products.

- Customized Raw Material Services: In addition, Zhuji Gaohui Machinery Co., Ltd. also provides customized raw material solutions for customers, ensuring that the performance of HDPE pipe fittings can be adjusted according to the needs of different projects.

Extrusion Molding

Zhuji Gaohui Machinery Co., Ltd.'s production plant is located in Zhuji City, Zhejiang Province, and boasts over 50 high-efficiency production equipment, dedicated to providing customers with high-quality HDPE pipe fittings. During the production process, Zhuji Gaohui Machinery Co., Ltd. employs the extrusion molding process to ensure the perfect quality and precision of every HDPE pipe fitting.

- Production Lines and Equipment: The company is equipped with advanced extrusion production lines capable of processing different specifications of HDPE pipe fittings, including electrofusion fittings, butt welding fittings, and threaded fittings. Zhuji Gaohui Machinery Co., Ltd. ensures that every pipe meets strict quality standards through precise temperature control systems and advanced screw design.

- Precision Pipe Mold Design: Zhuji Gaohui Machinery Co., Ltd. pays special attention to pipe mold design to ensure the dimensional accuracy and surface smoothness of each pipe. The company can manufacture large-diameter pipe fittings up to 1200mm according to customer needs, meeting the requirements of projects of different scales.

- Efficient Production and Delivery: With over 50 production machines and an experienced production team, Zhuji Gaohui Machinery Co., Ltd. can guarantee on-time delivery and flexibly handle the production needs of large-volume orders. Whether it's a large-scale construction project or a small pipeline installation, Zhuji Gaohui Machinery Co., Ltd. can provide high-quality pipe fittings in a timely manner.

Post-processing and Inspection

Zhuji Gaohui Machinery Co., Ltd.'s quality control system is one of the core elements of the company's success. All HDPE pipe fittings undergo rigorous quality testing to ensure their performance and quality meet international standards. The company has complete testing equipment and a senior technical team to conduct comprehensive testing on each batch of pipe fittings produced, ensuring compliance with relevant standards.

- Dimensional Accuracy and Appearance Inspection: Zhuji Gaohui Machinery Co., Ltd. strictly controls the dimensional accuracy, wall thickness, and appearance of each product. Each pipe fitting undergoes high-precision laser measurement to ensure that the dimensions meet customer requirements.

- Pressure Testing and Durability Verification: The company also conducts pressure tests, pressure resistance tests, and sealing tests to ensure that the products can be used stably in different working environments. Especially for HDPE pipe fittings used in high-pressure pipeline systems or drinking water pipeline systems, they must meet strict pressure resistance and corrosion resistance performance requirements.

- Quality Certification: All HDPE tubes and pipe fittings produced by Zhuji Gaohui Machinery Co., Ltd. comply with relevant domestic and international quality standards, such as ISO 4427, ASTM F 1055, etc., meeting the needs of different industries and regions.

Connection and Installation

Zhuji Gaohui Machinery Co., Ltd. not only produces HDPE pipe fittings but also provides customers with complete pipeline application solutions, including pipe connection technology, installation guidance, and technical support.

- Connection Methods: Zhuji Gaohui Machinery Co., Ltd. offers a variety of pipe connection methods, including:

- Heat Fusion Connection: By heating the joints of the pipe and fittings, they are melted and connected together, ensuring the sealing and pressure resistance of the joint. Butt Fusion Welding: This method connects the ends of pipe fittings by heating them to a high temperature, ensuring high strength and good sealing at the joint. It is suitable for large-diameter pipeline systems.

- Electrofusion Connection: Using electrofusion fittings, this method connects pipes and fittings through electrical heating. It is suitable for various industrial pipeline systems and offers excellent durability and pressure resistance.

- Pipeline Installation Guidance and Support: Zhuji Gaohui Machinery Co., Ltd. not only provides high-quality pipe fittings but also offers professional pipeline installation technical support to its customers. Whether it's product selection, installation plan design, or technical problems encountered during installation, Zhuji Gaohui Machinery Co., Ltd. can provide detailed solutions.

Overseas Market Expansion and Services

In recent years, Zhuji Gaohui Machinery Co., Ltd. has actively expanded its overseas markets by participating in international exhibitions. Its products have successfully entered several countries, including the Netherlands, Vietnam, the Philippines, Indonesia, Malaysia, the Maldives, Nigeria, Thailand, and Pakistan, and have received high praise from customers.

- Global Customer Support: Zhuji Gaohui Machinery Co., Ltd.'s products are not only bestsellers in the domestic market but also enjoy a good reputation in the international market. The company has expanded its international market through exhibitions, online marketing, and direct customer cooperation.

- ODM and OEM Services: Zhuji Gaohui Machinery Co., Ltd. also provides ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services to global customers. Whether it's customizing HDPE pipe fittings according to customer needs or providing complete pipeline system engineering, Zhuji Gaohui Machinery Co., Ltd. can provide professional and customized solutions for customers in different fields.

- Long-Term Cooperative Relationships: Zhuji Gaohui Machinery Co., Ltd. has established long-term cooperative relationships with many international customers, ensuring that its products can operate stably in different environments worldwide. The company focuses on long-term cooperation with its customers and continuously improves the quality of its products and services to meet the needs of different regions.

Physical Properties of HDPE Tubes

Mechanical Properties

- Tensile Strength: The tensile strength of HDPE is typically between 25-40 MPa. For some high-grade HDPE (such as PE100), the tensile strength can reach over 40 MPa. Tensile strength determines the pipe's ability to deform under external force and is an important indicator of whether the pipe can withstand high loads.

- Flexural Strength: HDPE tubes have high flexural strength and are usually suitable for applications requiring a certain degree of bending (such as pipes that need to bypass obstacles). HDPE tubes are not easily broken or deformed during bending.

- Impact Resistance: HDPE tubes have excellent impact resistance. Even in low-temperature environments, HDPE tubes can maintain strong impact resistance,

making them stable and reliable even in harsh construction environments.

Thermal Properties

- High Temperature Resistance: The high-temperature resistance of HDPE is generally below 80°C. Long-term exposure to high-temperature environments will cause HDPE tubes to soften and deform, making them unsuitable for transporting high-temperature fluids.

- Linear Expansion Coefficient: Due to the high linear expansion coefficient of HDPE tubes, significant temperature changes may cause changes in the pipe length. The impact of temperature changes on the pipe needs to be considered during design.

Chemical Properties

- Chemical Corrosion Resistance: HDPE exhibits extremely strong resistance to most common chemical substances (such as acids, bases, and salt solutions), making it particularly suitable for chemical plants and wastewater treatment systems.

- Water Resistance: HDPE is almost non-absorbent and can resist the erosion of most water-soluble substances, therefore it is widely used in water supply pipes, irrigation pipes, etc.

Electrical Properties

- Electrical Insulation: Due to the excellent electrical insulation properties of HDPE, HDPE tubes are often used for cable protection and conduit in power facilities.