What are the common application areas of HDPE fittings?

The corrosion resistance, wear resistance, and aging resistance of HDPE pipe fittings make them play an important role in many industries and application fields.

Water Treatment and Transportation:

- Tap Water Pipelines: HDPE pipe fittings are commonly used in tap water supply systems, especially in urban pipeline networks that require long-term stable water supply. Due to its excellent corrosion resistance, HDPE effectively prevents water pollution, pipe rusting, and other problems caused by metal pipes, ensuring the purity of the water.

- Rainwater Drainage Systems: In rainwater collection and drainage systems, HDPE pipe fittings, due to their toughness and corrosion resistance, can withstand various climatic conditions for a long time, avoiding problems such as pipe leakage and rupture.

- Water Treatment Plants: HDPE pipes are used in various processes in water treatment plants, such as the transportation of chemicals in sewage treatment and water purification processes. Its chemical resistance makes it perform well in environments dealing with various water qualities and acidic/alkaline water flows.

Natural Gas and Oil Transportation:

- Natural Gas Pipelines: HDPE pipe fittings can withstand the pressure and temperature fluctuations generated during natural gas transportation and are not corroded by natural gas, reducing the risk of leakage. They can be safely buried underground, avoiding the hidden dangers caused by corrosion and leakage problems in traditional metal pipes.

- Oil Transportation: In the transportation of oil, HDPE pipelines provide a more economical and efficient alternative. Due to the flexibility and high-pressure resistance of HDPE, it can adapt to different geological conditions and complex environments, especially in oil-rich regions, where HDPE pipelines are widely used in oil transportation systems.

Agricultural Irrigation:

- Irrigation Systems: In agricultural irrigation, HDPE pipe fittings are widely used in drip irrigation, sprinkler irrigation, and other systems. The flexibility and corrosion resistance of HDPE make it suitable for various soil and climate environments, especially in areas with water scarcity. The long lifespan and high-pressure resistance of HDPE pipes can greatly improve the efficiency of irrigation systems.

- Orchards and Greenhouses: HDPE pipe fittings are also widely used in orchard and greenhouse irrigation systems. They can effectively reduce water waste by precisely controlling the water flow, while increasing crop yields.

Chemical Transportation:

- Chemical Industry: HDPE pipes are widely used in the chemical industry, particularly for transporting chemical liquids (such as acids, bases, and salts). Due to HDPE's chemical resistance, many chemical plants choose HDPE pipes to avoid the corrosion problems associated with traditional steel and iron pipes in chemical transportation.

- Wastewater Discharge: In wastewater treatment and discharge, HDPE fittings effectively prevent chemical leaks, avoiding environmental pollution. They are particularly suitable for handling toxic and highly corrosive wastewater and sewage.

Mining:

- Tailings Transportation: In the mining industry, HDPE fittings are often used in tailings transportation systems. Due to HDPE's wear resistance and corrosion resistance, it can withstand various substances in the ore, preventing corrosion or wear of the pipes.

- Ore Extraction: In the ore extraction process, HDPE fittings are also used for the efficient transportation of ore slurry. Compared to traditional steel pipes, HDPE pipes have lower maintenance costs and a longer service life.

Sewage Treatment and Wastewater Transportation:

- Sewage Discharge: HDPE fittings are widely used in sewage treatment and discharge systems. They can effectively withstand corrosive substances in sewage, avoiding corrosion and leakage problems.

- Industrial Wastewater Treatment: Many industrial enterprises choose HDPE pipes for wastewater treatment and discharge because they can withstand wastewater with complex chemical compositions and effectively reduce maintenance costs.

What are the advantages and disadvantages of HDPE fittings compared to fittings made of other materials?

When choosing pipe materials, several factors must be considered, including the application environment, cost, and durability.

Comparison of HDPE and PVC fittings

Advantages:

- Better impact resistance: HDPE fittings have significantly higher impact resistance than PVC fittings. Even in low-temperature environments, HDPE fittings maintain their flexibility and are less prone to breakage, while PVC fittings may become brittle and crack in cold conditions.

- Stronger UV resistance: HDPE pipes typically contain UV stabilizers, effectively resisting ultraviolet radiation from sunlight, making them suitable for outdoor installation. PVC fittings, however, are prone to aging and reduced strength when exposed to UV light for extended periods.

- Suitable for high-temperature environments: While PVC pipes can withstand certain temperatures, HDPE pipes maintain stable performance at relatively higher temperatures. For example, HDPE fittings maintain good toughness at temperatures up to 60°C, while PVC fittings may soften and deform.

Disadvantages:

- Higher cost: Due to the higher manufacturing process and raw material costs of HDPE fittings, their initial investment is usually higher than that of PVC fittings, which can impact budgets, especially in large-scale projects.

- More difficult installation: The installation of HDPE fittings typically requires specialized equipment and techniques (such as heat fusion welding), while PVC fittings can be connected using simple adhesive methods, making installation relatively easier and faster.

Comparison of HDPE and steel pipe fittings

Advantages:

- Corrosion resistance: HDPE fittings exhibit superior corrosion resistance in chemical and humid environments. In contrast, steel pipes are susceptible to rust due to moisture and oxygen in the air. HDPE effectively prevents rusting and corrosion, especially when in prolonged contact with corrosive liquids or gases.

- Lightweight and easy to install: HDPE fittings are significantly lighter than steel pipes, making transportation, handling, and installation more convenient, reducing labor and time costs. Steel pipes are relatively heavy and require additional lifting equipment. Low Maintenance Costs: Due to the corrosion and wear resistance of HDPE pipes and fittings, they require virtually no maintenance during long-term use. Steel pipes, on the other hand, may require regular painting and rust removal, increasing maintenance costs.

Disadvantages:

- Lower Pressure Resistance: Steel pipes have significantly higher pressure resistance than HDPE pipes and fittings. Especially in high-pressure or specialized pipeline systems, steel pipes can withstand higher pressures, while HDPE pipes may be limited in high-pressure environments.

- Poor Thermal Stability: Although HDPE pipes and fittings can withstand certain temperatures, at very high temperatures (such as above 80°C), HDPE pipes will soften and deform, while steel pipes remain stable at higher temperatures.

How long is the typical service life of HDPE pipe fittings?

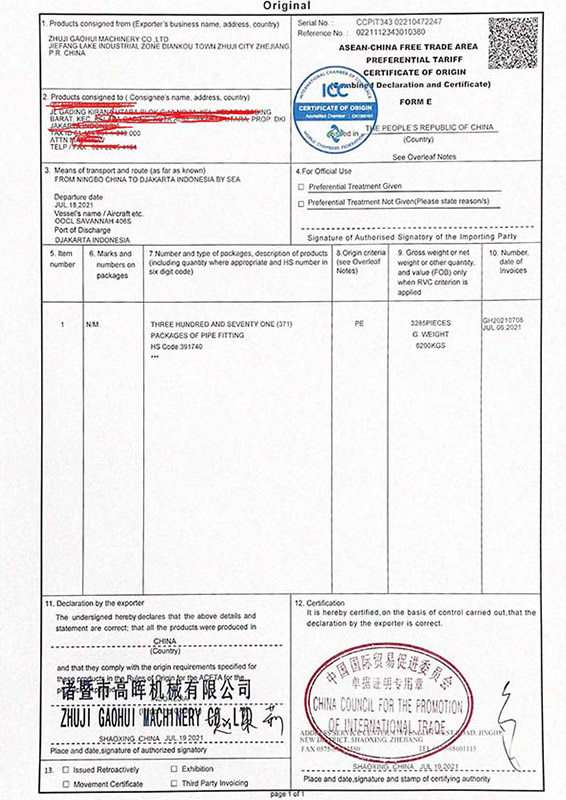

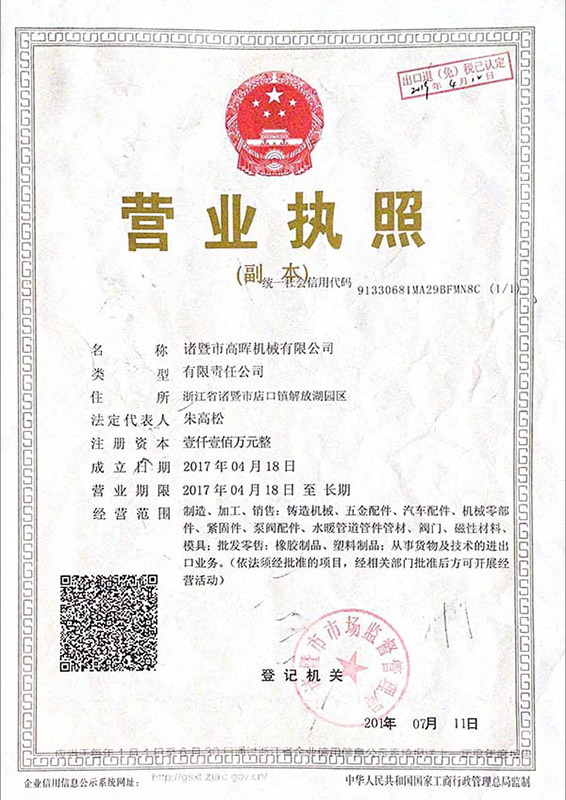

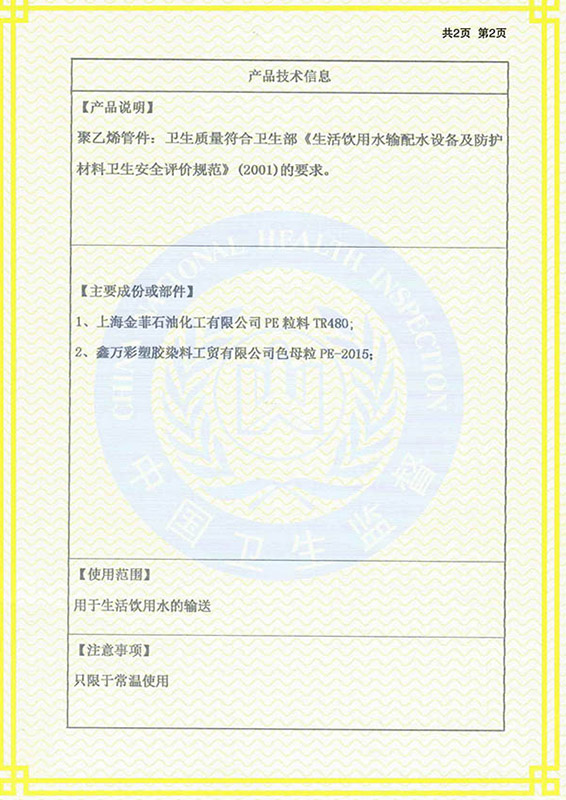

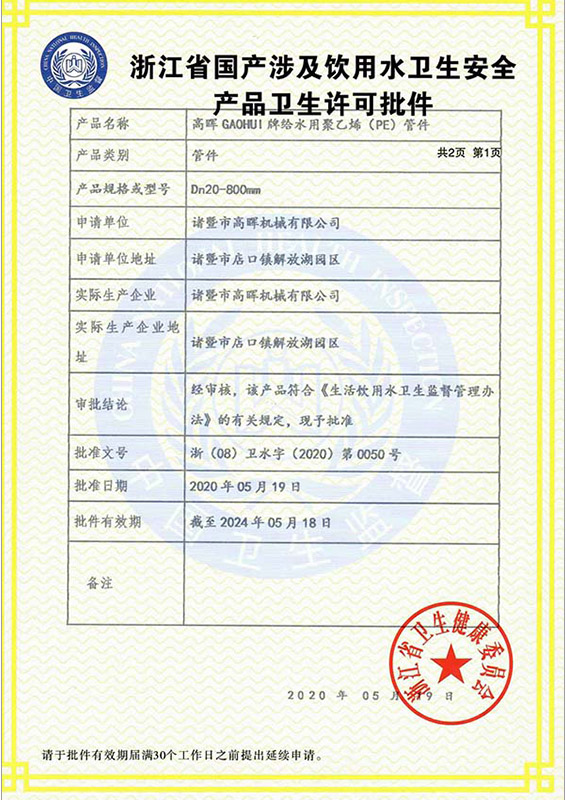

HDPE pipe fittings provided by Zhuji Gaohui Machinery Co., Ltd. have a service life of over 50 years. This is a significant reflection of the company's strict quality control standards and material selection during the design and manufacturing process. The company guarantees a 50-year service life for its HDPE pipe fittings under normal operating conditions, allowing customers to enjoy high-quality fittings and reduce long-term maintenance and replacement costs when choosing products from Zhuji Gaohui Machinery Co., Ltd.

Service Life of HDPE Pipe Fittings:

According to the technical and product data provided by the company, the 50-year service life of HDPE pipe fittings manufactured by Zhuji Gaohui Machinery Co., Ltd. under normal operating conditions is based on several factors, including:

- Corrosion Resistance: Zhuji Gaohui Machinery Co., Ltd.'s HDPE pipe fittings use high-quality raw materials and have excellent chemical corrosion resistance, maintaining good performance in various water and wastewater environments. Even in piping systems handling corrosive liquids such as strong acids and bases, HDPE pipe fittings can operate stably for a long time, greatly extending the service life of the pipeline.

- UV Resistance: Zhuji Gaohui Machinery Co., Ltd. adds UV stabilizers to its HDPE pipe fittings to ensure that the products can be used outdoors for extended periods without aging or cracking. This is especially important for piping systems that need to be exposed to sunlight for long periods, particularly in agricultural irrigation or open-air wastewater discharge systems, where HDPE pipe fittings maintain long-term durability.

- High Pressure Resistance: Zhuji Gaohui Machinery Co., Ltd.'s HDPE pipe fittings can withstand high internal and external pressures, suitable for various pressure rating piping systems. Whether in water supply, natural gas transportation, or wastewater treatment processes, the pressure resistance of HDPE pipe fittings ensures that they do not crack or deform during long-term use.

Factors Affecting Service Life:

- Environmental Conditions: The service life of HDPE pipe fittings is significantly affected by environmental factors. The fittings produced by Zhuji Gaohui Machinery Co., Ltd. are precisely designed to adapt to different climates and environmental conditions. Especially in high-temperature, high-humidity, or acidic/alkaline environments, Zhuji Gaohui Machinery Co., Ltd.'s HDPE pipe fittings can still maintain their high strength and stability, extending their service life.

- Use and Maintenance: Correct installation and regular maintenance of HDPE pipe fittings are also key to extending their service life. Zhuji Gaohui Machinery Co., Ltd. provides professional pipeline application solutions to help customers better design and maintain pipeline systems, ensuring that the pipe fittings operate normally within their expected service life.

Zhuji Gaohui Machinery Co., Ltd.'s Quality Control and Technical Support:

- Strict Quality Control: Zhuji Gaohui Machinery Co., Ltd. adheres to meticulous quality control, ensuring that every batch of HDPE pipe fittings meets international standards. The company uses over 50 advanced production equipment, coupled with an experienced team of workers, to guarantee product quality stability and timely delivery. For export markets, Zhuji Gaohui Machinery Co., Ltd. provides products that meet European, Asian, and other regional standards, ensuring that global customers receive the same high-quality products as the domestic market.

- Technical Support and Service: Zhuji Gaohui Machinery Co., Ltd. not only provides high-quality HDPE pipe fittings but also offers customized engineering systems and pipeline application solutions to its customers. Whether it's OEM customization needs or standard product selection, Zhuji Gaohui Machinery Co., Ltd.'s professional team can provide timely and professional support to ensure that every customer's needs are met.

Application Fields and Markets:

- Domestic and International Markets: Zhuji Gaohui Machinery Co., Ltd.'s HDPE pipe fittings are widely used in various fields such as tap water, natural gas, sewage, and agricultural irrigation, with a service life of 50 years. In the domestic market, Zhuji Gaohui Machinery Co., Ltd.'s products have received high praise from customers in numerous projects; at the same time, Zhuji Gaohui Machinery Co., Ltd. is actively expanding its overseas markets, and its products have been exported to the Netherlands, Vietnam, the Philippines, Indonesia, Malaysia, the Maldives, Nigeria, Thailand, Pakistan, and many other countries, and have gained a good reputation.

- Long-term and Stable Supply: Zhuji Gaohui Machinery Co., Ltd. can provide HDPE pipe fittings with a maximum diameter of up to 1200mm according to customer needs, and guarantees a stable supply of products. In large-scale projects, Zhuji Gaohui Machinery Co., Ltd.'s products can meet high engineering standards, ensuring the long-term stable operation of the system.