|

|

|

|

|

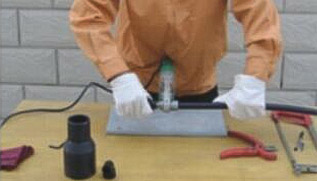

| 1. Check the surface quality of the pipes, ensure that the connecting parts are clean and undamaged, and that the fracture surface is flat and smooth without burrs. Measure the depth of the socket and mark it on the surface of the pipe. | 2. Use a dedicated scraper to treat the surface of the connecting part of the pipe with a new surface layer around the pipe mouth. The mouth should be chamfered, with a groove of 30 and a surface groove length of not more than 2.0mm. | 3. Wipe the socket surface of the pipe fittings with a dry cloth and clean the surface. | 4. Insert the pipes and fittings into the heater without rotation at the same time, and heat the connecting parts. | 5. Heat to the predetermined time, pull out the pipes and fittings, quickly, smoothly and evenly push the pipes into the fitting socket, forming a convex ring around the socket. Pipes and fittings can only proceed to the next step after exceeding the specified cooling time. |

English

English русский

русский عربى

عربى